Making a difference in patient care through 4D bioprinting

Navigating the Path to Breakthroughs

Expanding the horizons of tissue engineering beyond 3D

When asked about his inspiration for starting with 4D bioprinting, Dr. Kaushik Chatterjee highlights his background in materials engineering and the advancements in 3D printing as important factors. Dr. Chatterjee believes that the advancements with bioprinting has opened the possibility for creating previously unattainable products and devices.

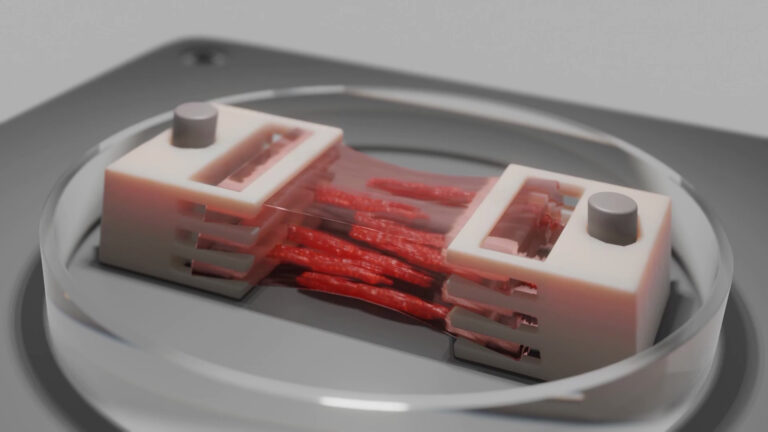

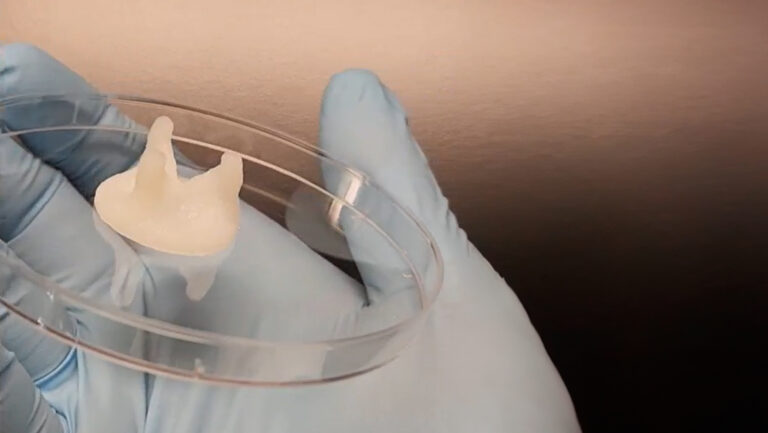

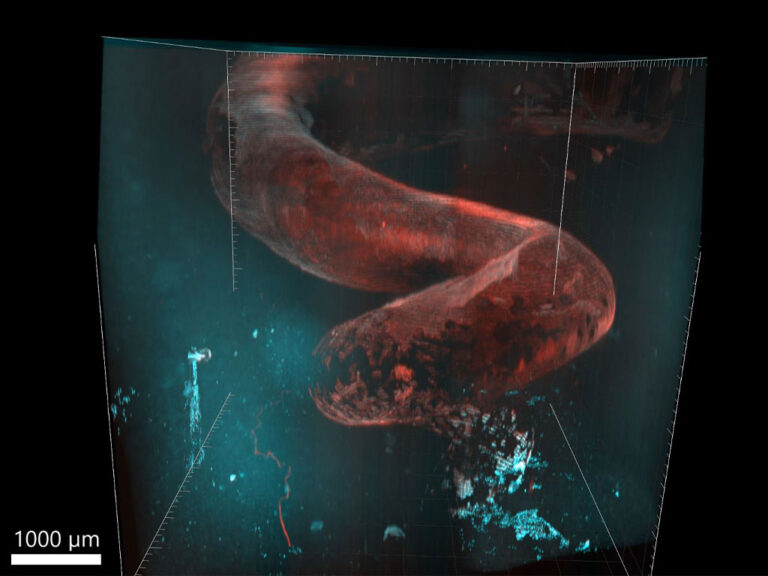

With 4D bioprinting, he envisions the ability to generate dynamic structures, paving the way for complex tissue development and personalized medical devices. Driven by a deep passion for innovation and the desire to enhance human health, Dr. Chatterjee is dedicated to making significant contributions to the field of medical technology.

Navigating the challenges of advancing from 3D to 4D bioprinting

Optimization, Translational Research, and Clinical Relevance

Embarking on the journey of 3D bioprinting and transitioning to 4D bioprinting presents a significant challenge: the need to optimize multiple variables. It involves the optimization of materials, printing parameters, and the selection of cells. Moreover, it’s important to consider the relevance of the technology to clinical applications, including the needs of clinicians and patients. Achieving this requires translational research, which can be difficult in a new field where regulatory processes are also not well-established.

Nonetheless, overcoming these challenges is essential to unlock the potential of bioprinting in regenerative medicine. This is why Dr. Chatterjee highlights the need for finding a supportive industry partner with the right technology and expertise as crucial for accelerating the advancements he sees, and exploring the vast potential of 4D bioprinting.

Exploring the Boundaries of Bioprinting

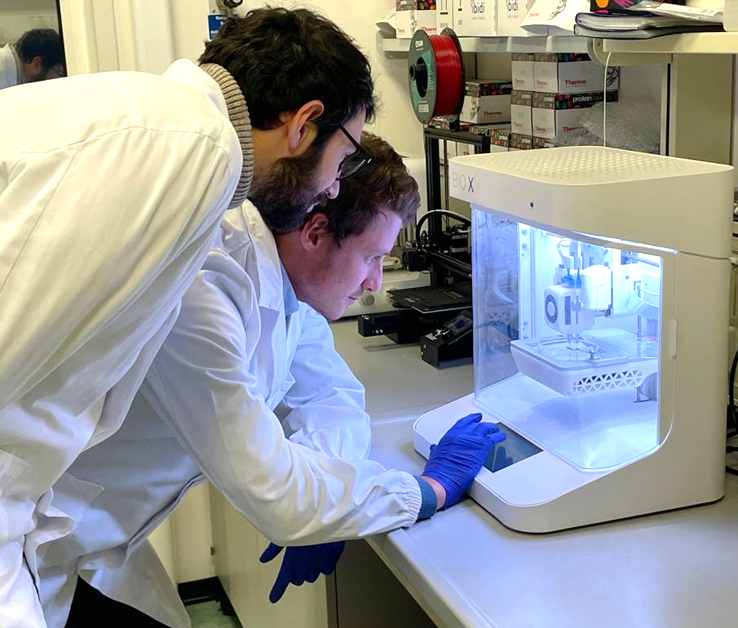

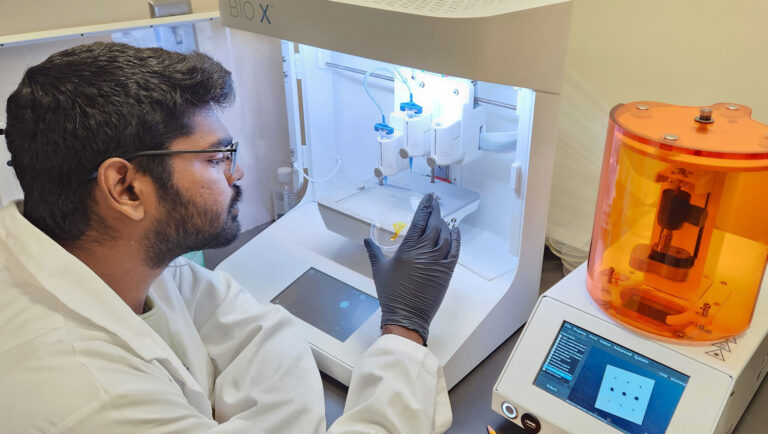

"I began my 3D bioprinting journey by acquiring the BIO X at the beginning of 2020."

- Dr. Kaushik Chatterjee

He embarked on his 3D bioprinting journey in 2020 with the acquisition of a BIO X. Starting with the printing of 3D scaffolds, he expanded his research capabilities by incorporating the LUMEN X, a DLP bioprinter, later the same year. The combination of these printers allowed Dr. Chatterjee to explore 4D bioprinting techniques for creating structures beneficial in surgery and healing.

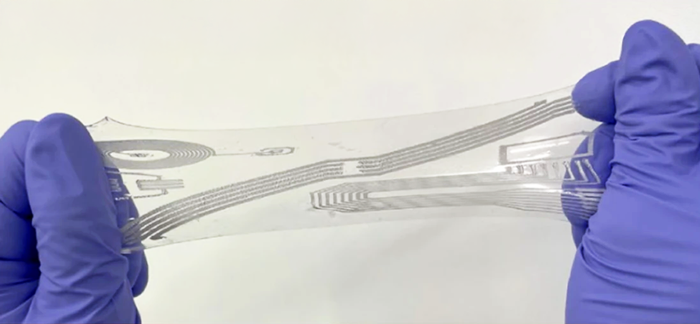

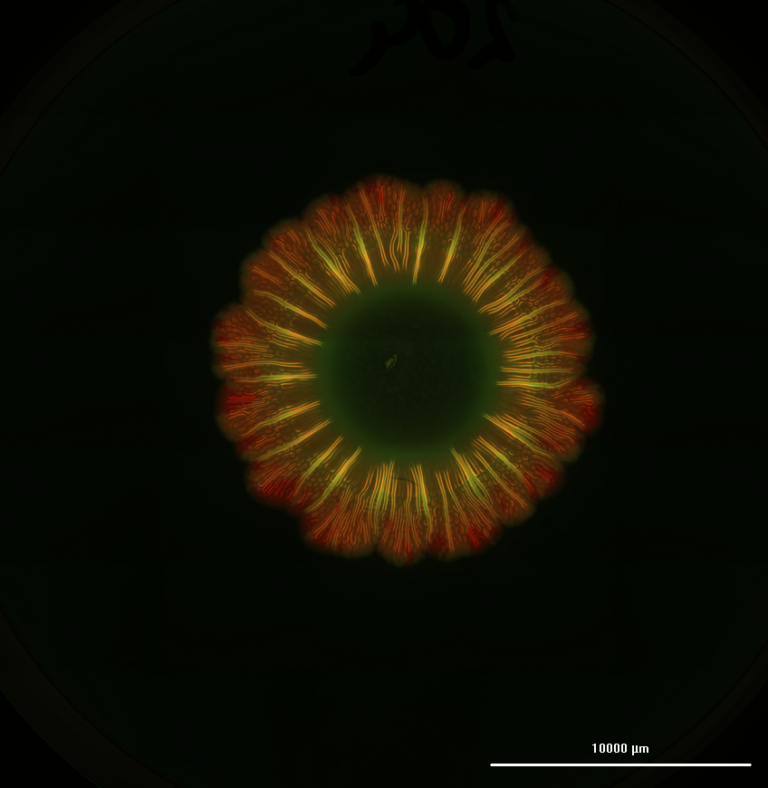

The BIO X impressed Dr. Chatterjee with its three different printheads, enabling multi-material printing—a feature not commonly found in other bioprinters. He also highlighted the potential of optimizing the bed temperature to modify material properties and the thermoplastic printhead’s ability to support plastic and 4D printing, facilitating research across various materials, including hydrogels and plastics.

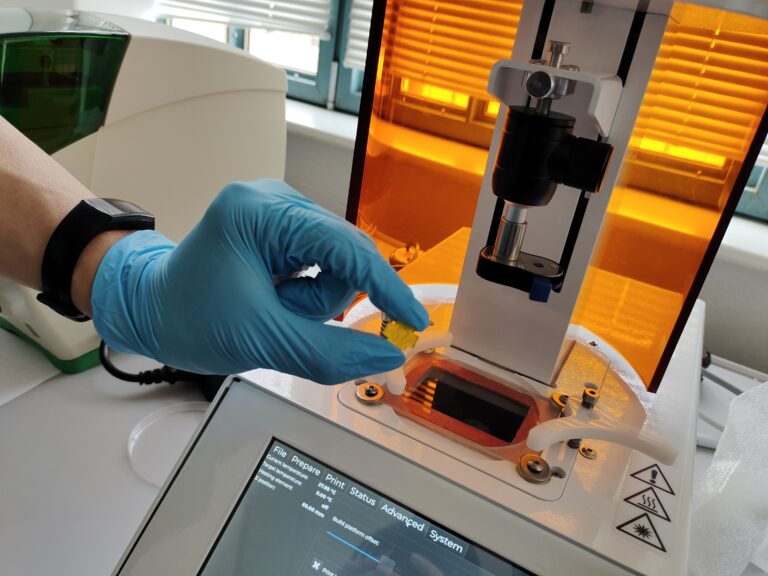

Regarding the LUMEN X, Dr. Chatterjee emphasized its distinction from other DLP printers, specifically designed for resin printing. He praised CELLINK for offering the only true DLP bioprinter on the market, equipped with a cell-friendly light source crucial for encapsulating live cells and photocuring. This eliminated the need for modifying an existing 3D printer for live cell printing and saved valuable time in his research.

His work using the BIO X and LUMEN X has resulted in notable publications in Advanced Healthcare Materials, showcasing his research on programmable shape-morphing hydrogels and visible light-based 4D-bioprinted tissue scaffolds.

“Access to quality healthcare is limited, especially in countries with large populations and remote geographic areas such as in India. 3D and 4D bioprinting holds the potential to offer hope and opportunities to meet clinical needs for such populations.”

- Dr. Kaushik Chatterjee

Bridging the Gap between Research and Drug development

Dr. Chatterjee’s journey in bioprinting demonstrates his commitment to pushing the boundaries of the field and leveraging innovative technologies to advance regenerative medicine and tissue engineering. He emphasizes the abundance of opportunities available to individuals from diverse backgrounds to utilize and enhance technology. Industry players are deeply intrigued by the potential of 4D bioprinting. Traditional animal model systems often fall short in accurately predicting the efficacy and safety of drugs. As a result, the industry recognizes 4D bioprinting as one of the most promising technologies to explore. Its ability to generate dynamic structures offers a new dimension in understanding and advancing drug development, revolutionizing the field and paving the way for safer and more effective treatments.

Dr. Kaushik Chatterjee is taking significant strides in bridging the gap between research and drug development. His next steps involve harnessing the high-throughput capabilities of BIONOVA X to study the impact of light exposure on various materials, enabling efficient exploration of material properties. Collaborating with hospitals, he aims to guide them through the necessary procedures for implementing 3D bioprinting, focusing on utilizing GMP grade bioinks from CELLINK for potential human applications. To pave the way for human trials, meticulous lab experiments will be conducted to identify optimal results. To learn more about his groundbreaking research, refer to his publication preprint on 4D printed magnetic composites available on ChemRxiv.

Additionally, Dr. Chatterjee has established Centre of Excellence at the Indian Institute of Science, dedicated to raising awareness about 3D bioprinting and inviting biopharma companies to witness and embrace this transformative technology. In his mission to disseminate knowledge, he plans to organize public events that foster community engagement and promote the concept of bioprinting.

Regardless of background.

We’re here to support and guide you on your bioprinting journey! Unleash the Power of 4D Bioprinting Technology and join us in making a difference in patient care.