Applications / Personalized Medicine

3D Bioprinting Is Reshaping Personalized Medicine

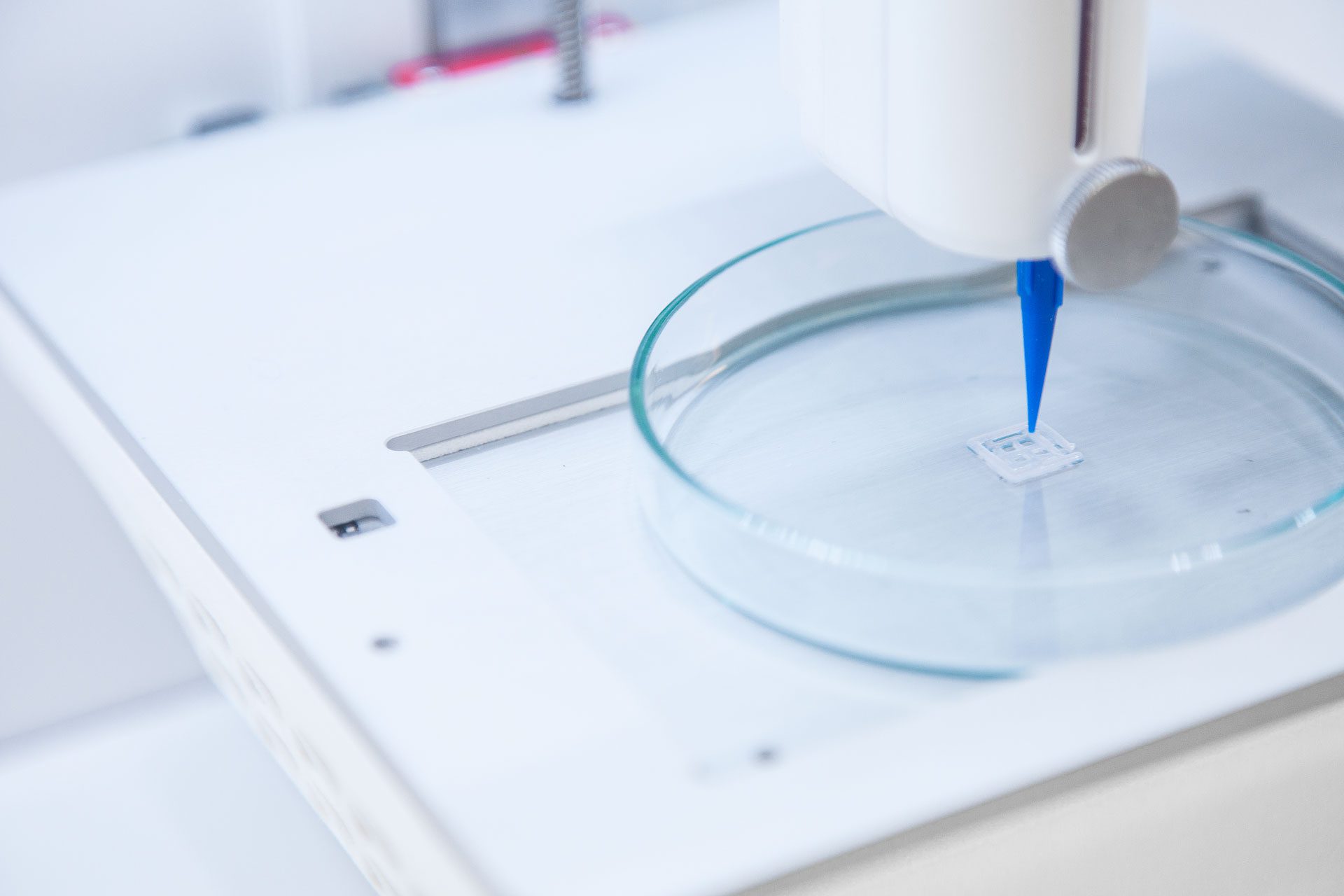

3D bioprinters and biodispensers are facilitating the biofabrication of personalized medicine therapies, including biomedical implants, biosensors and smart drug delivery devices.

Merging biocompatibility and additive manufacturing

Personalized medicine is moving us away from one-size-fits-most healthcare toward more targeted treatments tailored to the individual patient—not just in terms of size but also physiologically. The branch of personalized therapies encompasses everything from replacement organs to biomedical implants to biosensors to smart drug delivery devices. But even though these therapies do not have to incorporate living cells, they must consist of biomaterials that are both biocompatible and non-cytotoxic. While traditional 3D printers produce similarly intricate devices in other fields, most of these resin-based devices cannot handle biomaterials. For example, the most abundant protein in the human body, collagen, also happens to be very temperature and pressure sensitive. Plus, keeping cells viable necessitates a sterile environment. Thankfully, 3D bioprinters have merged the additive manufacturing principle of 3D printers with biocompatibility, enabling major personalized medicine breakthroughs in the last decade.

Bioprinted drug-eluting patches offer automated dosing and localized delivery

A 3D bioprinted smart drug delivery device can safely interact with a patient’s biological system and can help increase dosing compliance, a common challenge with self-administered oral or topical treatments. Plus, by enabling localized delivery, 3D bioprinted smart drug delivery devices can minimize side effects associated with the systemic use of antibiotics.

Heart patches

In an exemplary application of 3D bioprinting for drug delivery, a group of Finnish researchers used the BIO X to bioprint a cardiac patch for delivering drugs to damaged heart muscles for as long as 5 months, helping to regenerate myocardium after an infarction. Another bioengineering team based out of Johns Hopkins Hospital achieved similar results with a 3D bioprinted cardiac patch and reported 100% survival rate 4 weeks after implantation in an animal model.

Brain cancer patches

The ability to deliver drugs locally via patches is not limited to cardiac tissue. In fact, one CELLINK customer used the BIO X to 3D bioprint a hydrogel-based mesh for delivering a cancer drug at the site of a glioblastoma brain tumor over several weeks.

3D bioprinted wound-healing patches proactively prevent infections

Two novel uses of 3D bioprinting are set to disrupt wound-healing protocols as well as advance personalized medicine, and both paired the versatile BIO X with biodegradable polymers.

Piercing stud sleeves

A team from the University of Prince Edward Island developed biopierce, a bioabsorbable scaffold printed on the BIO X that prevents piercing infections by covering piercing studs with the antimicrobial mupirocin, in the form of a drug-loaded PLGA (poly-lactic-co-glycolic acid) scaffold. The biopierce would enable sustained delivery of the antibiotic as the polymer degraded and the drug would be absorbed only at the site of the piercing. Researchers believe this protocol could be used for other wound dressings as well.

Wound-healing patches for diabetics

A team of researchers in Belfast, Ireland, used the BIO X and FDA-approved polymer polycaprolactone to produce biodegradable wound-healing patches for the localized and sustained delivery of antibiotics directly to the site of infected diabetic foot ulcers. The one-and-done feature of these bioactive wound dressings would prevent infections with no need for medically trained personnel to change bandages.

Mass-producing stem cells

Extrusion-based bioprinters and biodispenser are not the only 3D technologies facilitating breakthroughs in biomedical science. DLP-based 3D bioprinters, like the LUMEN X and BIONOVA X are also contributing. One customer is revolutionizing stem cell research by culturing adult stem cells in large quantities on a 3D scaffold produced in high throughput using the light-based LUMEN X bioprinter. The modular design of these building scaffolds means that additional blocks can be added indefinitely, enabling cells to proliferate, migrate and produce ECM with no need for passaging.

Future outlook

Biosensors and bioelectronic technologies

As researchers work on revolutionizing point-of-care systems with integrated biosensors in 3D bioprinted microfluidic organ-on-a-chip devices, CELLINK bioprinters will continue to play a major role in bioengineering with or without human cells.

Delve deeper

Customer spotlight: Mass-produced Stem Cells: A Gateway to Personalized Medicine

Webinar: An Emerging Technology for Fabricating Personalized Pharmaceuticals

Product page: LUMEN X

Customer publication: Emulating Human Tissues and Organs: A Bioprinting Perspective Toward Personalized Medicine

Customer publication: Versatility on Demand: The Case for Semi-solid Micro-extrusion in Pharmaceutics