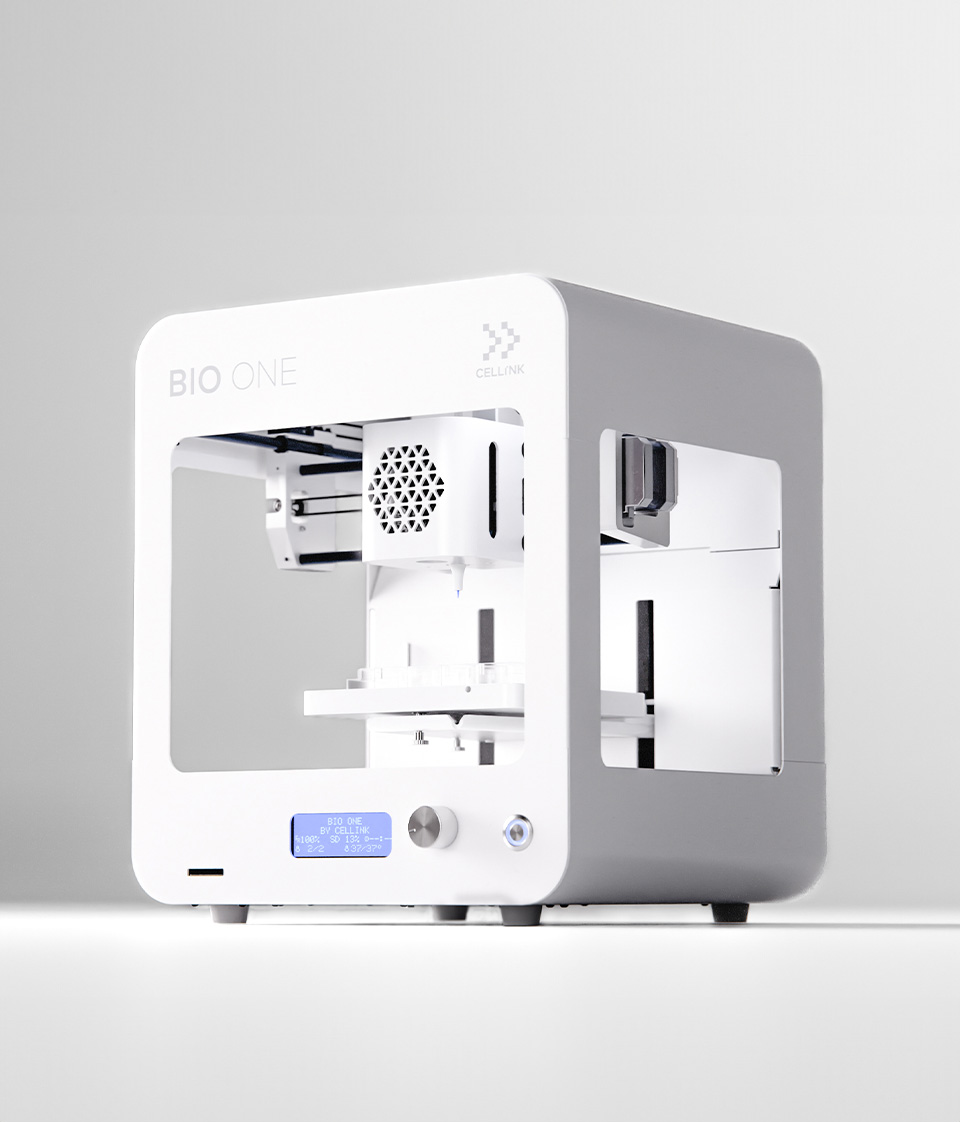

Eliminating the barriers to 3D cell culture

With exceptional cooling capabilities, precision syringe-based extrusion and an intuitive, easy-to-use desktop software in DNA Studio Core, the BIO ONE brings a new level of ease in the transition to 3D cell culture.

Designed for printing temperature-sensitive materials, the BIO ONE enables scientists to develop 3D models that replicate in vivo environments, contributing to accelerated discoveries.

Join in the paradigm shift that will accelerate discoveries across life science research.

01

RT* - 0 °C

Printhead Temperature Range

* Room/Ambient temperature

02

RT - 65 °C

Printbed temperature range

03

0.1 μL

Volume step

Empowering researchers to take the step into another dimension

Conventional approaches such as traditional cell culture or animal testing have limitations, prompting the demand for more precise in vitro models in the life sciences. BIO ONE is an instrument that empowers researchers regardless of previous knowledge in constructing more physiologically relevant models, while reducing cost and ensuring more accurate data.

Cooling capabilities

Rapidly cool the BIO ONE printhead down to 0 °C and maintain the temperature throughout the print. With a novel design, ensure temperature stability till the tip of the nozzle from start to finish.

Material flexibility

The BIO ONE is designed to be an open material platform, meaning that users can load any material into a syringe and dispense it, including temperature-sensitive materials like collagen.

Precision extrusion

Enable total control over your print with the high-precision mechanical extrusion of the BIO ONE. The mechanism boasts an impressive 0.1 μL volume step.

Heated printbed

Extend construct stability and cell viability for heat-responsive materials through thermal crosslinking, using the built-in printbed heating ranging from RT – 65 °C.

Maximized reproducibility

Enable highly reproducible structures with limited print-to-print variation and human error, by both leveraging the precision and by saving your protocols to the software.

DNA Studio Core

Powered by DNA Studio Core, the BIO ONE has ease-of-use as its core principle, which makes it easier than ever to enter the world of 3D cell culture.

The BIO ONE Printhead

Precision in every print

The BIO ONE is equipped with a mechanically driven syringe-based printhead, ensuring precision and reproducibility in 3D model development. Mechanical extrusion offers superior accuracy when compared to pneumatic extrusion.

01

A 0.1 μL volume step and mechanical extrusion through a syringe for enhanced precision and reproducibility.

02

Rapid and stable cooling of the entire printhead, maintaining any temperature from RT to 0 °C throughout the print.

03

Excellent control and accurate printing of both low and high viscous biomaterial with consistent flow rates.

04

Minimizing material waste by giving you the ability to precisely control the exact material volume of your print.

Printing a variety of construct types

Robust, reliable, and small enough to fit in your biosafety cabinet or on the benchtop, the BIO ONE is perfect for printing droplets, droplet arrays and lattices, allowing easy production of organoids, spheroids and tissue constructs that accelerate your research.

Powered by

DNA Studio Core

With DNA Studio Core, users have an easy-to-use desktop software which guides them through the entire bioprinting journey.

FEATURE HIGHLIGHTS

– Multiple printing modes, facilitating droplet or 3D construct printing

– Compatible with multiple file types

– User-friendly UI for an intuitive experience

Biomaterials & Consumables

Built as an open material platform

BIO ONE is built from the ground up with flexibility in mind, with the intent that users can add any biomaterial and dispense it. This is achieved through DNA Studio Core, where we can easily modify printing parameters like retraction volume and extrusion rate. Couple this with printhead cooling capabilities and a heated printbed to further the system’s biomaterial flexibility.

The cooled BIO ONE printhead, integrated into the bioprinter, plays a crucial role in maintaining the structural integrity of collagen during printing. The cooling technology effectively prevents denaturation or degradation of the collagen. CELLINK offers multiple collagen materials, providing researchers with versatile options for various applications, with limited batch-to-batch variability.

Matrigel® is commonly used in cellular studies today. Its gelatinous nature – rich in growth factors and bioactive components – necessitates precise handling during the bioprinting process. The integration of the cooled BIO ONE printhead prevents gelation and minimizes the risk of clogging, resulting in consistent and reproducible printed constructs with high print fidelity.

Matrigel is a registered trademark of Corning, Inc.

The BIO ONE is designed for printing with any biomaterial of your choice. When using a custom material – whether developing your own or buying from another vendor – it is important to take note of the features of the BIO ONE. Namely, the Printhead temperature range from RT – 0 °C and the Printbed temperature range from RT – 65 °C play a key role in determining material compatibility. If you are interested in finding out if your material will work well with the BIO ONE, reach out here.

Explore our materials →

Key Applications

Unlock the advantages of 3D cell culture and reap the benefits of reproducibility for greater insights across various applications.

Tissue Engineering

Engineering 3D tissue models

Bioprinting has become an essential tool in tissue engineering. With its user-friendly interface, the BIO ONE is the ideal stepping stone to start creating 3D tissue models. The easy creation of 3D tissue models such as cartilage or skin is a great boon in the research of a tissue’s regenerative properties, the study of wound healing, and developing in vitro alternatives to animals for cosmetic testing.

Material Science

Developing the next gen of biomaterials

The open platform of the BIO ONE allows users to freely develop and readily use their own materials, without any workarounds or fees. Relying on non-proprietary syringes and nozzles, it is possible to print with any bioink. The software allows fine tuning of various printing parameters, including volume and flow, which means you can create protocols for most materials. This ensures the system can be used in multiple areas of material sciences, from bioink development and soft robotics to smart materials.

Drug Discovery

Better insights into the best candidates

With printing capability on up to 384-well plates, the BIO ONE enables researchers within the field of drug discovery to easily increase the number of replicates and gain a more accurate understanding of compound activity. This accelerates the drug discovery process by ensuring only the best candidates are carried along to clinical trials. Simply print an array of droplets to investigate drug delivery in easily reproducible in vitro models.

Resources

Application Note

Developing collagen contraction assays by bioprinting droplet and ring constructs

In this application note, we are looking into how the BIO ONE can be leveraged to automate contraction-based assays and cell culture models.

Read the application note now

Technical Specifications

| 3D bioprinting technology | Temperature controlled, syringe-based extrusion |

| Printhead volume | 2.5 mL* |

| Theoretical volume unit step | 0.1 µL |

| Printhead dispensed volume CV (Coefficient of Variation) | < 5% @ 10 µL for water |

| Printhead temperature range | 0°C - RT ± 1°C |

| Printhead flow rate range | 1 - 50 µL/sec |

| Build surface compatibility | Petri dishes and multi-well plates (6 to 384 wells) |

| Build volume | 130 mm x 80 mm x 50 mm |

| Printbed temperature range | RT - 65 °C |

| Photocuring system | 405 nm LED |

| Calibration options | Manual and Automatic |

| Linear positioning precision | XY: 10 µm, Z: 2.5 µm |

| Software | DNA Studio Core |

| Supported file formats | .gcode, .stl, .obj, .amf |

| Desktop application compatibility | Windows 11 and Windows 10 V20H2 onwards |

| Connectivity | USB, SD-card |

| Operating temperature range | 15 - 30 °C |

| Power supply | Input: 100-240VAC, 50/60Hz, 2.0A Output: 24VDC, 6.67A, 160W |

| Outer dimensions (D x W x H) | 325 mm x 370 mm x 380 mm |

| Weight | 15 kg |

*CELLINK catalogue #CL-CS-3SYR-ST-200 or BD Syringe catalogue #309658

Unrivaled portfolio for your research needs

As the bioprinting leader, we take pride in our extensive portfolio of bioprinting solutions which meets the diverse needs of laboratories worldwide. From light-based bioprinters to extrusion-based bioprinters and biodispensers, our portfolio is designed to cater to a spectrum of needs, ensuring that you have the right tools to achieve your project goals.