BIONOVA X

Uncovering the Depths of Biology with High Throughput In-Well DLP Bioprinting

Bringing Direct In-Well Printing to Light-based Bioprinting

The cutting-edge BIONOVA X is a high throughput, high speed and high precision DLP 3D bioprinter, bringing light-based bioprinting to an entirely new level.

By enabling multi-material bioprinting and multi-stiffness bioprinting, as well as live cell printing, users can recapitulate in vivo biomechanical properties with ease. The biofabrication of more accurate in vitro models enables greater results across the world of tissue engineering.

10 μm

Printing Resolution

6 - 96

Multi-well plate Support*

RT - 60 °C

Temperature Range

Unleash the Power of the BIONOVA X 3D Bioprinter

With the BIONOVA X, we are meeting the demand for more precise, biomimetic models for high throughput applications. We’re enabling the effortless recapitulation of microarchitectures, vasculature, and complex geometries, with live-cell printing capabilities, speed, and control.

Direct In-Well Printing

Increase throughput with the BIONOVA X through its in-well layer-less printing technology. Print directly in 6-, 12-, 24- and 96-well plates, depending on your research requirements.

Unmatched Resolution

Multi-material Printing

A crucial aspect to constructing certain biomimetic tissues is the need for multiple biomaterials. The enhanced precision of BIONOVA X enables multi-material printing.

Multi-stiffness gradients

With the introduction of grayscale printing, you can accurately tune the stiffness of your material and create biomechanical gradients that capture the finer details of in vivo biology.

Hassle-Free Setup

Cell-friendly printing

Using a 405 nm light source ensures minimal damage to cells during printing. Combined with printbed heating up to 60 °C, the BIONOVA X is fully compatible with cell-friendly biomaterials like GelMA.

Watch this short video to learn more about how the BIONOVA X works.

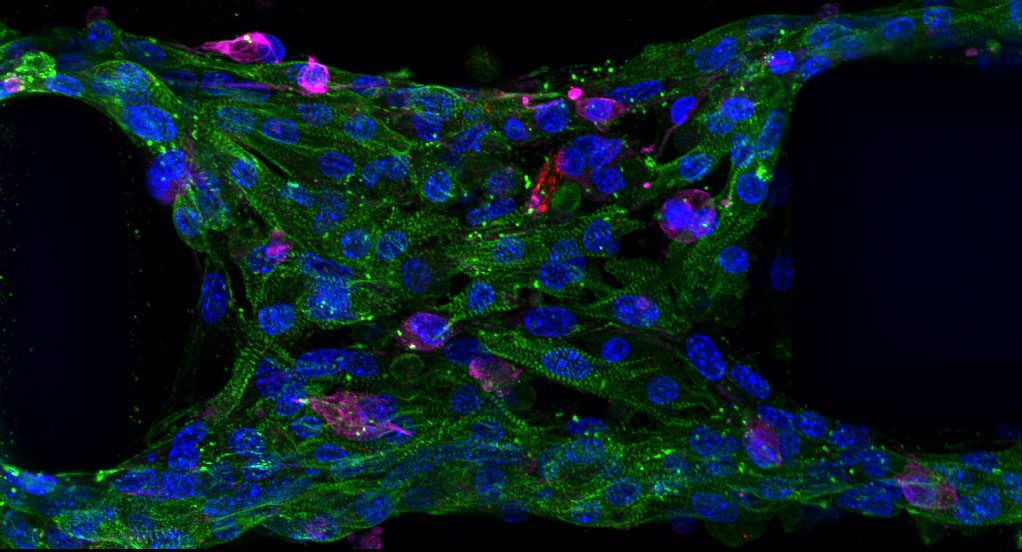

Micropatterning created with BIONOVA X in a 24-well plate. Micropatterns are particularly useful to direct cell geometry and interactions, create stiffness gradients, and study the effect of a microenvironment on cell behavior.

Biomaterials & Consumables

An open material platform designed for you

The BIONOVA X is an open material platform, meaning that you have the freedom to develop your own materials. We also offer ready-to-use photoinks based on materials like GelMA, PEGDA, Alginate and Hyaluronic Acid, with which you can begin printing in no time.

Explore our range of base materials and begin developing your own photoinks.

Our range of ready-to-use photoinks will have you up and researching in no time.

Printing probes and well plates – all your accessories.

Regenerative Medicine

From Medical Images to 3D Models

With the BIONOVA X, we are taking regenerative medicine to another level. As a result of multi-stiffness capabilities and multi-material printing, combined with live cell printing, BIONOVA X users can create realistic models that may eventually help regenerate aspects of our body. Thanks in part to its heated printbed, the BIONOVA X is excellent for use with biocompatible materials that promote cell proliferation, further enabling its use in both regenerative and personal medicine applications.

Disease Modeling

Recreate Disease-like Conditions Through Microarchitectures

The very high resolution of 10 μm enables greater control of developing microarchitectures within your biomimetic tissue models. This enables you to mimic any physiological abnormalities typically find in the disease you are studying, allowing even more disease-like conditions. By enabling this in up-to 96 structures per print, you can do this at greater outputs than ever before. Owed to multi-stiffness and multi-material capabilities, the BIONOVA X has the ability to recapitulate in vivo biomechanical properties of both diseased and healthy tissue within your in vitro models.

Featured Application Note

Bioprinting human microheart models for precision medicine and drug discovery

This in-depth application note demonstrates how leveraging the continuous printing mechanism unique to the BIONOVA X enables biofabrication of physiologically relevant cardiac constructs capable of enhanced maturation.

Micropillars were printed directly into the well plate, and iPSC-derived cardiomyocytes were seeded around them for models capable of contraction. This print is ideal for applications like drug testing and disease modeling.

Read the application note now

Create the Future of Health

Technical Specifications

| 3D Bioprinting Technology | Direct in-well layer-less printing with digital light projection-based technology | |

| Outer Dimensions (L x W x H) | 20.3” x 15” x 17.4”

515 mm x 380 mm x 441 mm |

|

| Weight | 41 kg (90 lbs) | |

| Well Plate Formats | 96 well plate, 24 well plate, 12 well plate, 6 well plate | |

| Build Volume (X x Y x Z) | 96 well plate | Ø 3 mm x 5 mm |

| 24 well plate | Ø 9 mm x 6 mm | |

| 12 well plate | 9 mm x 9 mm x 9 mm | |

| 6 well plate | 19 mm x 10 mm x 9 mm | |

| Printing Resolution (XY) | 10 μm | |

| Z-precision (motor driven) | 4 μm | |

| LED Wavelength | 405 nm (FWHM ±7.5nm) | |

| Intensity Range | 4 - 16 mW/cm² | |

| Heater Temperature | Room temperature to 60 °C | |

| UV-Sterilization | UV-C (270±10 nm) sterilization of chamber | |

| User Interface | Integrated Display | |

| Supported File Types | .stl, .png, .bmp, .jpg | |

| Display | 10” touchscreen, glove-friendly | |

| Connectivity | USB-A | |

| Power Supply Unit | 100-240VAC, 50-60Hz, 200W | |

* Multiwell plates with 6, 12, 24 and 96 wells are supported. The BIONOVA X does not support printing with 48 well plates.