A Bridge to Better Hearing

3D Bioprinted Hydrogel Models for Cochlear Implant Evaluation

Dr. Ulises A. Aregueta Robles and his team, as well as many others, see some key drawbacks with the use of animal models: intra-animal differences, long study periods, and a difficulty with extrapolating the results to human tissue responses. To overcome these issues within testing neuromodulation devices, and provide an alternative to animal testing, the team has set out to develop in vitro human tissue models. Here, they have created a model of human scala tympani, which can be used for testing cochlear implants.

Hydrogel Magician: A Quest to Transform Neural Interfaces

We’re putting a spotlight on Dr. Ulises A. Aregueta Robles, an accomplished early-career researcher at the Graduate School of Biomedical Engineering, University of New South Wales.

Dr. Aregueta Robles has long pursued the boundaries of hydrogel technologies, seeking to build on the diagnosis field and enable the creation of novel medical devices that improve the performance of bionic implants – such as cochlear implants.

Most of his work revolves around designing hydrogels for a better understanding of tissue regeneration. This involves adjusting the properties to suit the desired tissue, as well as enhancing their biocompatibility.

In this way, Dr. Aregueta Robles is poised to make significant contributions to the neural engineering field.

Quest for Improved Cochlear Implants and Minimizing Animal Testing

There is a lot of pressure from legal organizations (such as the FDA), regular people and researchers alike to minimize the use of animal testing, due to both animal rights concerns, its accuracy in replicating human tissue responses and the naturally limited availability of animal models.

When conducting a study today, even pre-clinical, it is important to consider animal models vs. in vitro models. As Dr. Aregueta Robles and his team began their work – they knew they wanted to replicate the inner ear with an in vitro human tissue model. However, that was no easy. The conventional methods of hydrogel fabrication proved insufficient to the task of replicating the complex structures and specific morphologies of the inner ear. This prompted Dr. Aregueta Robles to explore 3D bioprinting.

Using 3D bioprinting and CAD software, the team has developed a model of the inner ear which has the potential to be used for testing cochlear implants. By using 3D printing technology, they have produced a scalable and reproducible model which has the potential to facilitate high-volume testing while enabling a comprehensive assessment of variables. In turn creating a valuable alternative to animal testing.

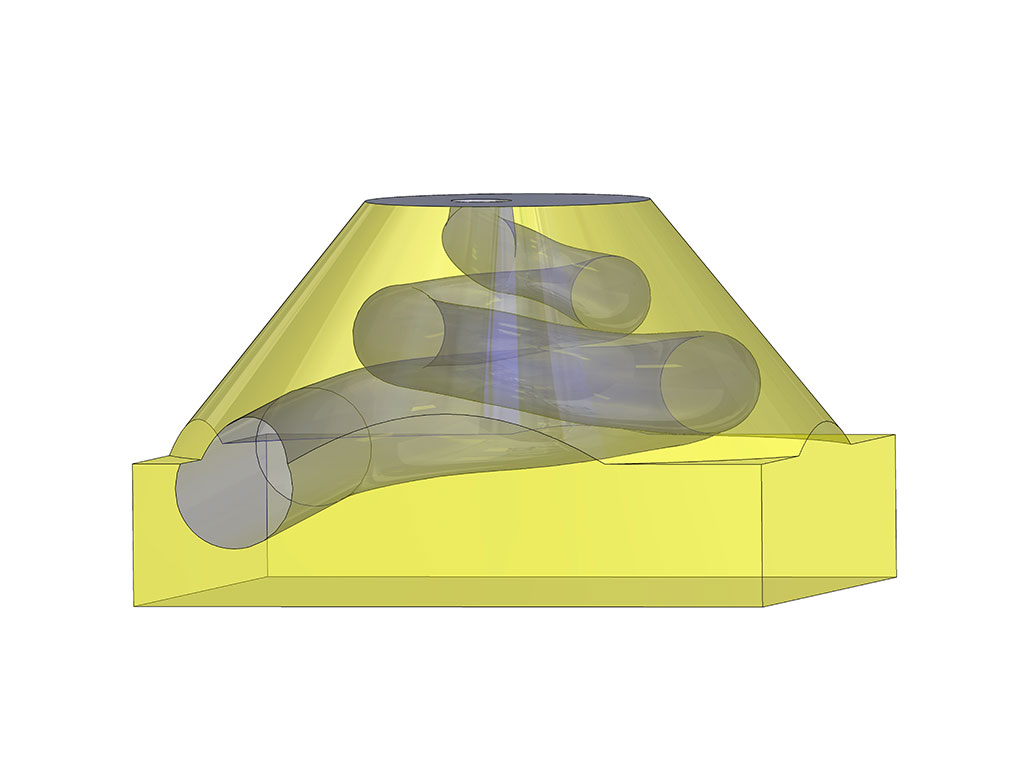

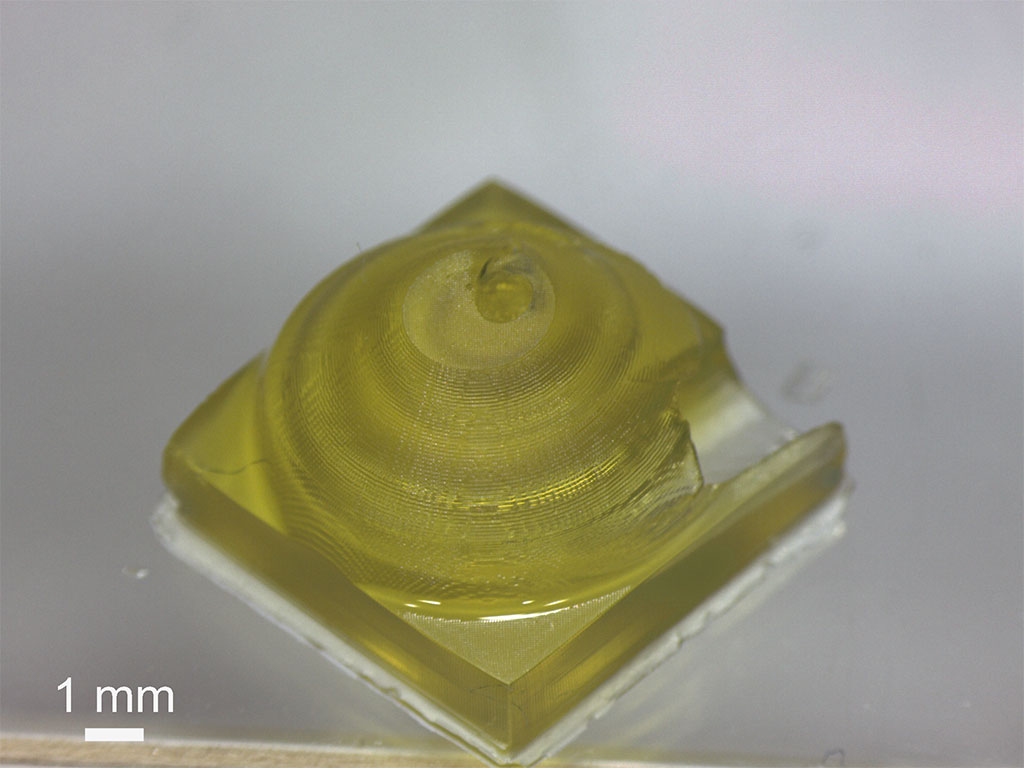

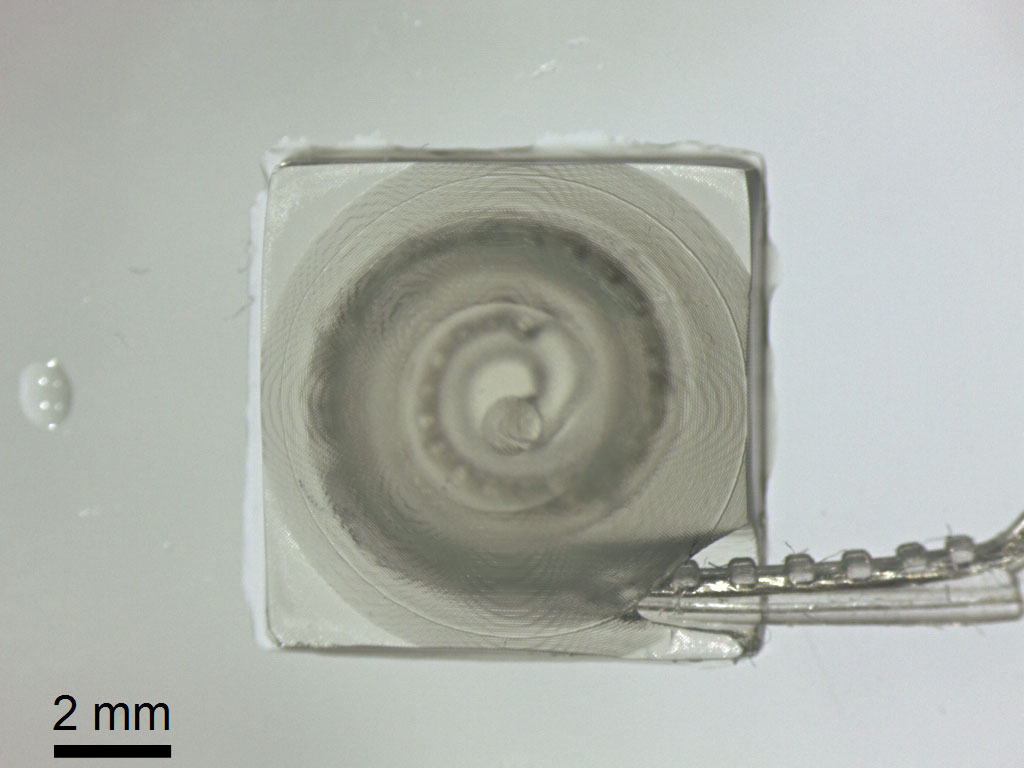

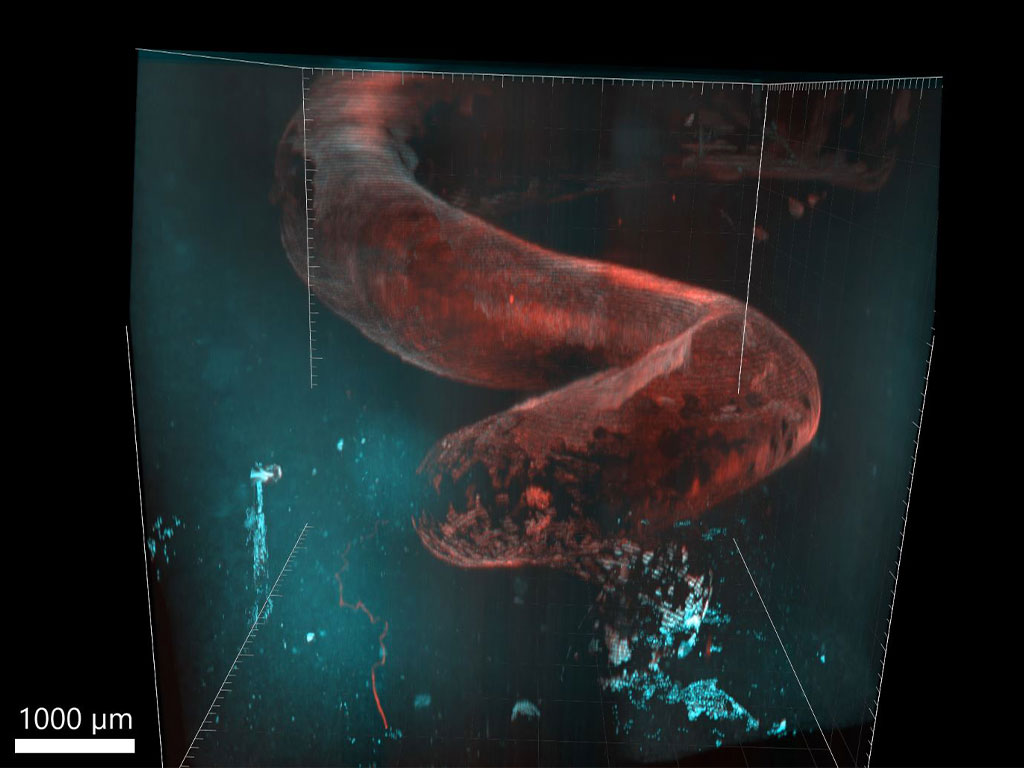

A

B

C

D

Figure 1 (A) 3D model of human scala tympani, where cochlear implants are commonly placed for effective stimulation. (B) Scala tympani model 3D printed with LUMEN X+ using an in-house tailored methacrylated Poly (vinyl alcohol) (PVA-MA) ink. (C) The model following removal of photoabsorber accommodating a human cochlear electrode array. (D) Fibroblasts (L929) grown in PVA-MA hydrogel co-polymerised with methacrylated gelatin, which was mould-cast onto a silicone template created via the 3D printed scala tympani model as described in [1].

Images reproduced from [1] with permission of the authors.

The Path to Advanced Implant Technologies

Dr. Aregueta Robles’ and the team’s research paper, Growing human-scale scala tympani-like in vitro cell constructs, opens up new avenues for advancement in the field. In the study, the team successfully printed human-scale structures which emulate the morphologies of the scala tympani, in which cochlear electrodes are commonly implanted.This was done while maintaining the hydrogel’s support for cell adhesion. These structures can also accommodate cochlear implants for future device testing.

By presenting this comprehensive model for assessing experimental variables which impact implant performances, this research can help propel the field forward. The challenges associated with bionic implants, such as increased impedance and material degradation, are addressed head-on.

“Understanding the interplay between biology, material, electrical performance and manufacturing processes in the lab before progressing to animal models or clinical validation.” – Dr. Aregueta Robles

While the research paper focuses on cochlear implants, the model in the articles serves as an in vitro model capable of evaluating a wide variety of devices: implants, nerve stimulators, brain-stimulating devices, and other technologies which involve electrode placement to restore neural motor functions.

Collaboration: A Key for Impact

Dr. Aregueta Robles credits his collaborations with esteemed universities as instrumental in the success of his team’s paper.

By leverage the expertise and guidance of their collaborators, they have been able to develop the model to align closely with the intended biological outcomes. This has, in turn, enhanced both the accuracy and relevance of the research.

Going away from the traditional method of pre-clinical testing (using the small size of a mouse’s inner ear), and developing their in vitro human scale scala tympani-like model, has enabled comprehensive electrode testing of neuromodulation devices prior to any implantation.

Without the help of experts, who knew what characteristics was needed from the structure, creating a biomimetic in vitro tissue would have been significantly more difficult.

Lighting the Path Forward

One of the key criteria Dr. Aregueta Robles prioritizes in tissue engineering is precision, specifically in terms of surface resolution. Smooth and accurately structured surfaces are crucial when incorporating cells into artificial structures, as the behavior of cells can be influenced by surface quality. Another consideration is the ability for solutions to travel through channels with the printed structures.

When exploring 3D bioprinting approaches, the LUMEN X stood out as an enticing solution with its impressive resolution. Recognizing that this was exactly what they needed – they decided to give it a try.

"LUMEN X is easy to operate - especially with its intuitive interface and the user-friendly nature."

– Dr. Aregueta Robles

Paving the way for human-biology replication and accessibility

Looking ahead, Dr. Aregueta Robles envisions further progress in his research journey focusing on the continuous development of tissue models. His ultimate goal is to create tissue models that accurately represent human biology while remaining accessible and easy to produce for researchers and individuals interested in utilizing them. These models can be readily adapted for use in various laboratory and industry settings, even for those unfamiliar with the specific research conducted. However, extensive research is still required to refine and enhance these tissue models.

By harnessing the power of the LUMEN X, Dr. Aregueta Robles achieves his team’s desired precision and resolution, propelling the research to new heights. As he continues on his path, the impact of his work holds promise for a future where healthcare is enhanced by innovative engineering solutions.

“Through innovative research and technological advancements, we can reshape the future of neural engineering and transform the lives of individuals with neural disorders.”

Publication

[1] Aregueta Robles UA, Bartlett-Tomasetig F, Poole-Warren LA. Growing human-scale scala tympani-like in vitro cell constructs. Biofabrication. 2023 May 9;15(3). doi: 10.1088/1758-5090/accfc0. PMID: 37094574.

Are you looking to incorporate bioprinting into your research?

Our experts will guide you in the right direction.