Empowering Highly Motivated Researchers

The Revolutionary Role and Benefits of 3D Bioprinters

Sometimes it takes courage to take a step into the unknown and go after a dream.

This is especially true in fields built on advanced technology, like 3D bioprinting. Many researchers are concerned that taking the step into bioprinting and 3D cell culture will be too difficult. They believe their lack of experience will hamper their ability to make the most out of the potential and capability of 3D bioprinting.

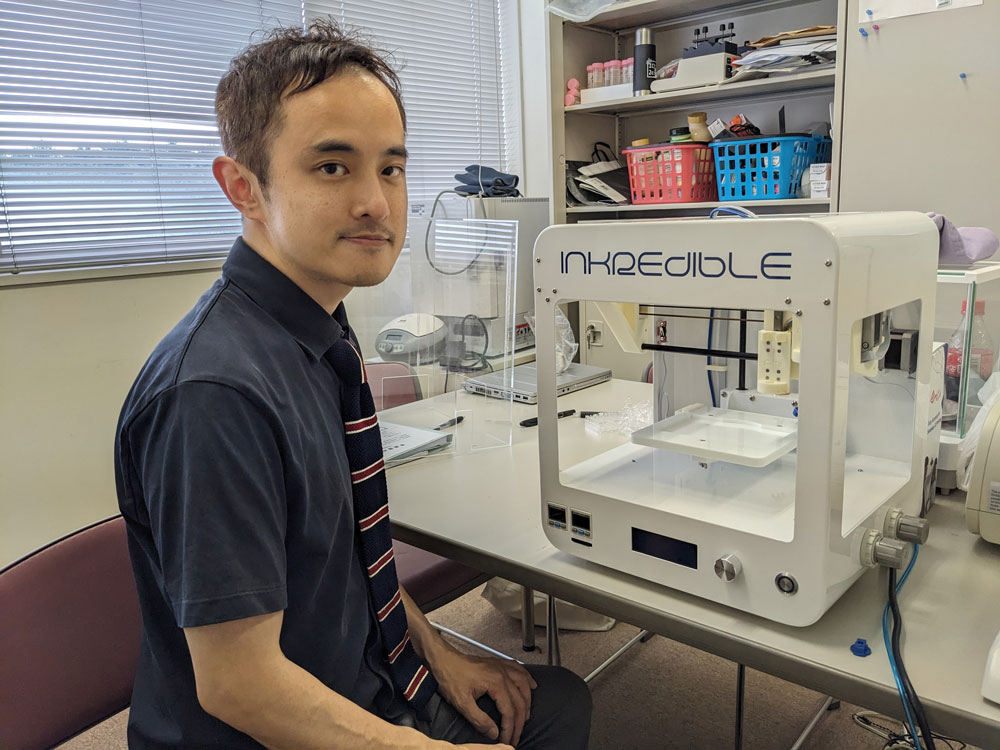

We have interviewed Takaaki Arahira, the Associate Professor of the Department of Information Networks, Faculty of Management and Information Sciences at Kyushu Institute of Information Sciences, who had the courage to take the first step into the world of bioprinting.

Bioprinting provided greater cell density uniformity without sacrificing on materials

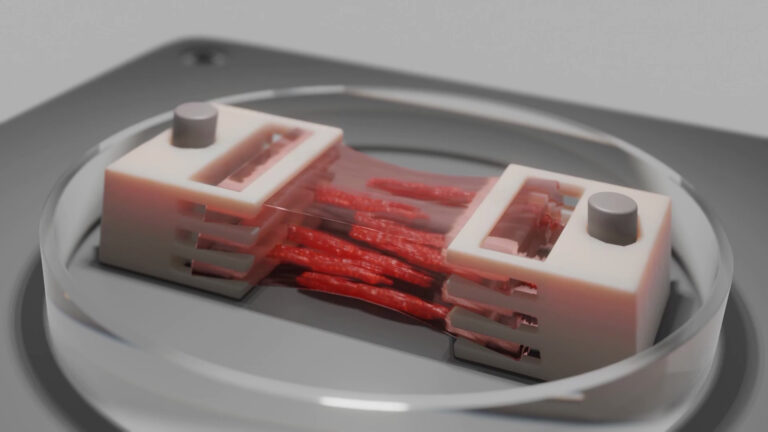

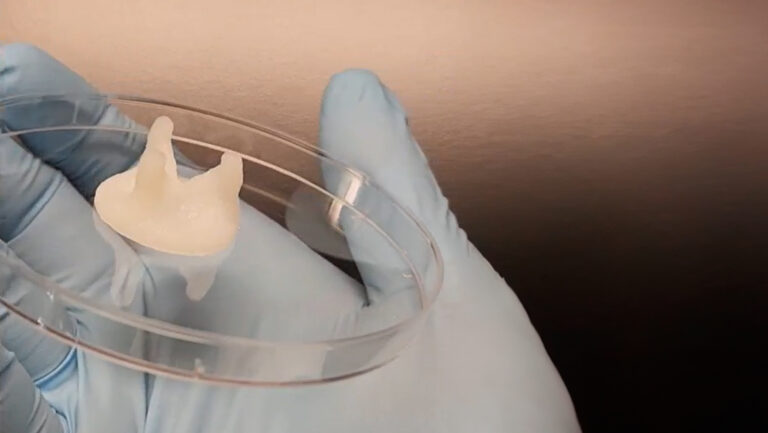

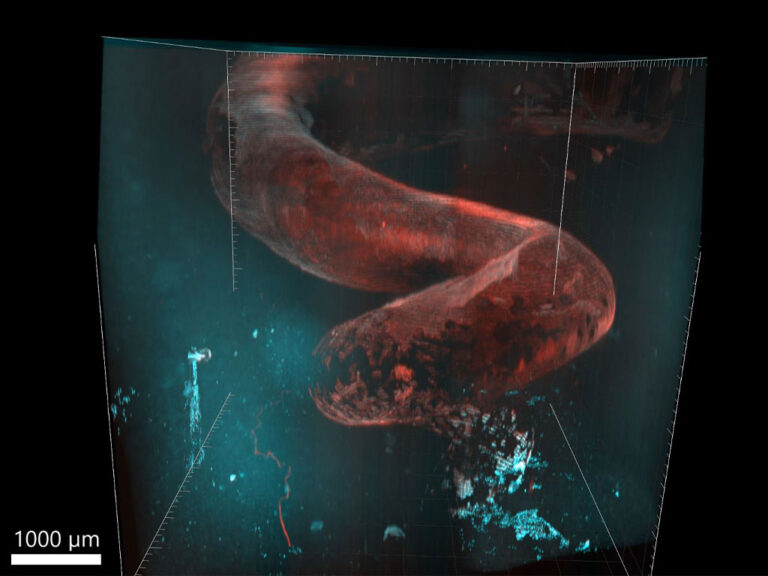

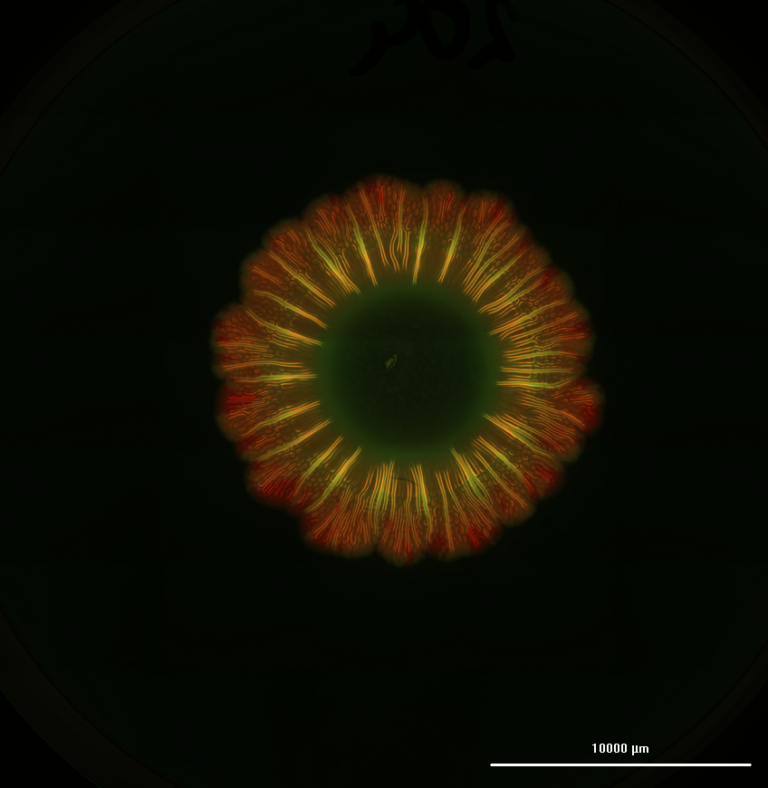

Dr. Arahira’s research area is in the field of biomechanics, which examines the mechanical strength of materials. In particular, he is examining materials used for bone and cartilage cells.

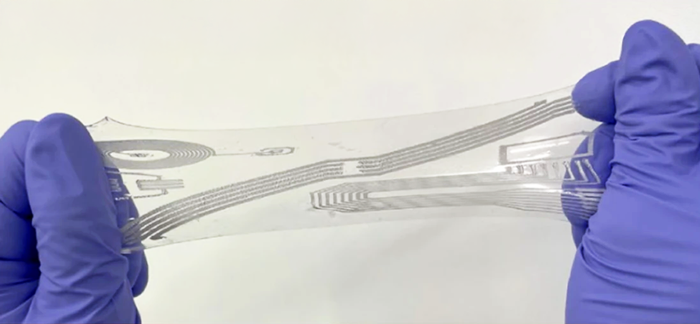

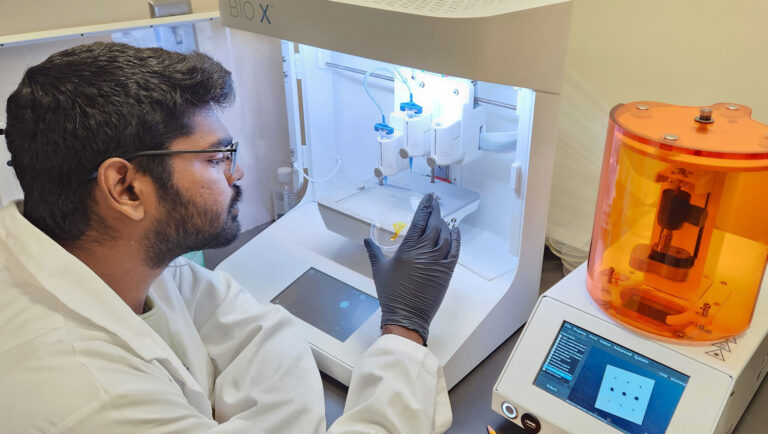

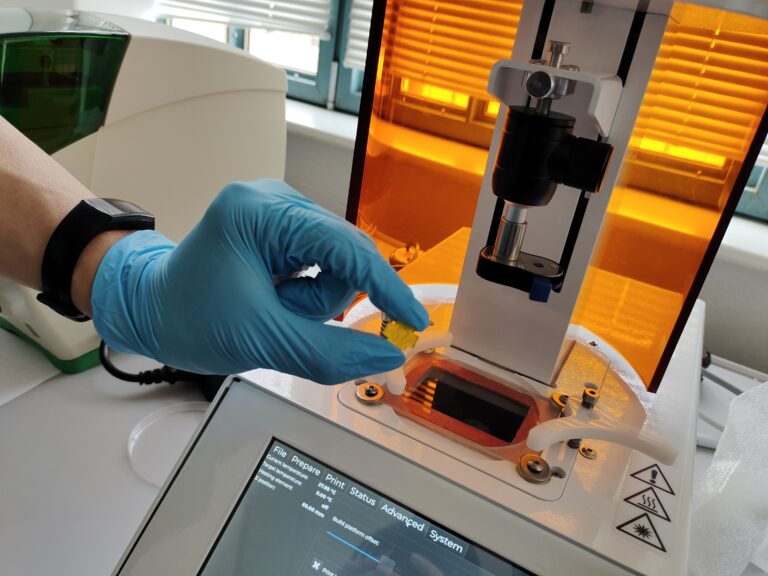

Dr. Arahira had been culturing cells and conducting research using porous collagen sponges since he was a student, but he felt that ensuring uniformity of cell density was a challenge. In particular, when cells were seeded from a specific direction, they grew in an unbalanced distribution, making it difficult to obtain accurate experimental results. Instead of approaching the problem from a materials design perspective, such as molecular structures that improve cell adhesion, he was looking for ways to improve the physical and structural aspects, which is his specialty. His mind went to extrusion-based 3D bioprinters, which he thought could solve this as the material would be mixed with the cells prior to printing, thus forming a uniform cell distribution throughout the tissue.

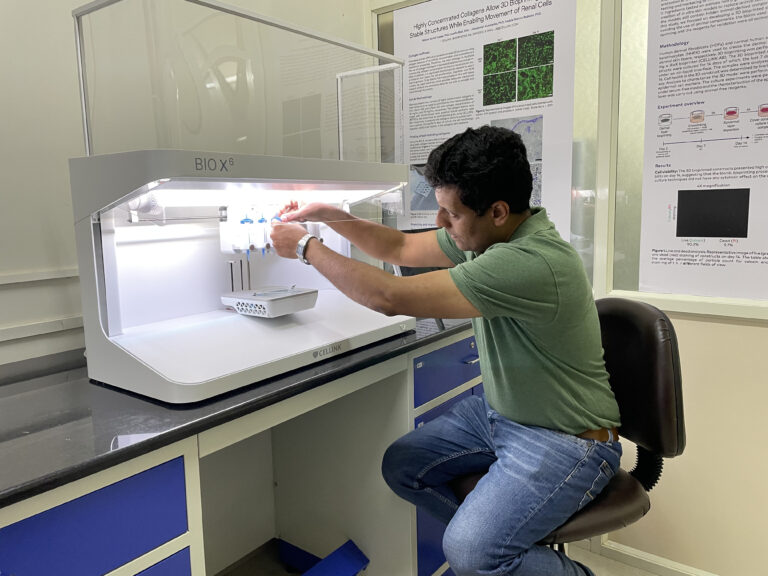

The reason for choosing a CELLINK printer was several, among them: The open material platform with multi-material printing capabilities, which allowed him to work with the materials and bioinks he wanted to. CELLINK’s large portfolio of bioinks, and inks for bone tissue, also played an important role.

Moving to a 3D bioprinting approach wouldn’t mean he was limited in scope – instead, it opened up a world of possibilities while making the step both comfortable and easy.

In particular, he credits the ability to modify the concentration and composition of the bioinks as a way to make the bioprinter highly versatile, and meeting the ultimate goal of Dr. Arahira.

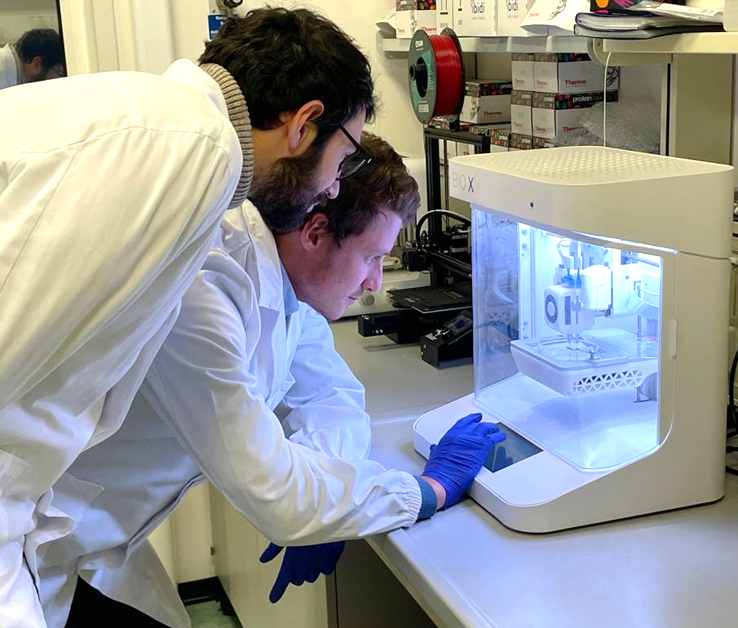

The size of the benchtop bioprinter impressed

When he first saw INKREDIBLE, Dr. Arahira was impressed by its small profile. The compact design and versatility of the device, which was different from conventional resin-based 3D printers and the traditional lab equipment, gave the INKREDIBLE a lot of potential for research development.

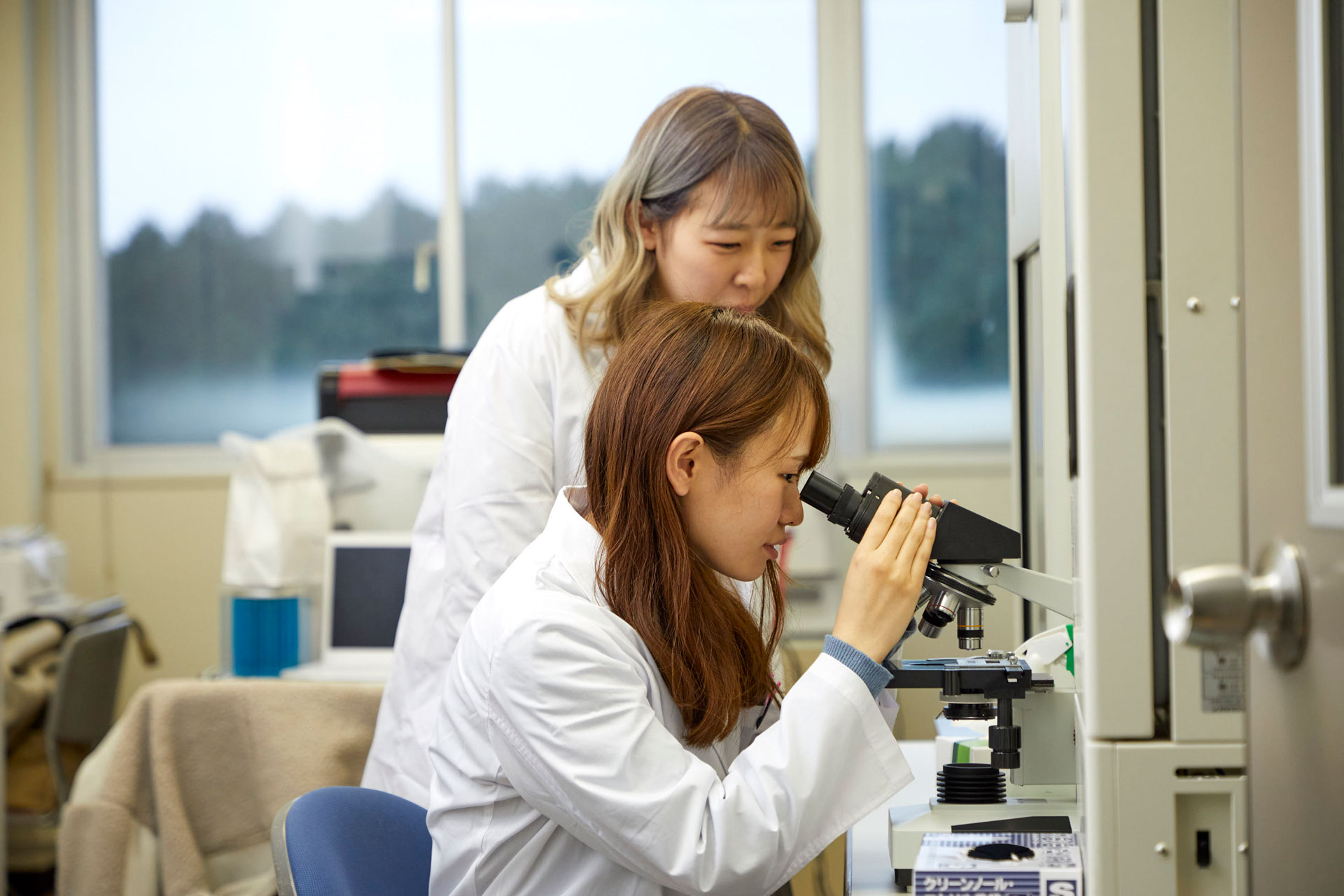

Changing students' attitude towards research

In addition to the professor’s research, the use of 3D bioprinter has significantly increased among the students in Information Sciences at the university. This includes students who are looking at medical applications of computer science, programmatic data analysis, mechanics studies, and human tissue development.

Dr. Arahira credits his CELLINK bioprinter with increasing interaction and cooperation among the students.

One of the challenges in using 3D bioprinters is to get the material to play along with the shape you are printing, and an understanding of both the material and the bioprinter is required to get it to work as expected. What this encouraged was something previously unseen within this student body, where a cooperative system was created to create generic guidelines for best practices. This strengthened the community, and the bioprinting knowledge and expertise among the students increased.

"It's easier than you can imagine"

To master the 3D bioprinter, the fine-tuning of printing parameters depending on bioink is necessary to print the desired construct. However, compared to the days of manual extrusion Dr. Arahira was previously doing, the efficiency and accuracy is greatly improved. Because INKREDIBLE can print nearly any biomaterial, Dr. Arahira now uses his own materials to print his constructs. He says that using the 3D bioprinter is easier than you can imagine, even for people with little to no knowledge of 3D printing. He encourages researches who are hesitant to not worry.

“3D printers are a very good tool as a learning experience because you can create what you imagine. Especially, the 3D bioprinter, which can relates to human tissue. So even people who have previously not aware they can contribute to the field of medicine can come up with clever ways to help people suffering from illnesses, by contributing with the discovery of new medical knowledge. It is a dream product.”

Dr. Arahira finishes off by saying that his experiments are progressing smoothly, and that he is working on his next paper.