World-leading precision and accuracy with 2PP bioprinting

CELLINK and Nanoscribe have reimagined two-photon polymerization (2PP) printing technology through a biologist’s lens. With Quantum X bio, you will explore bioprinting on the nano- and microscale.

Bringing your ideas to life

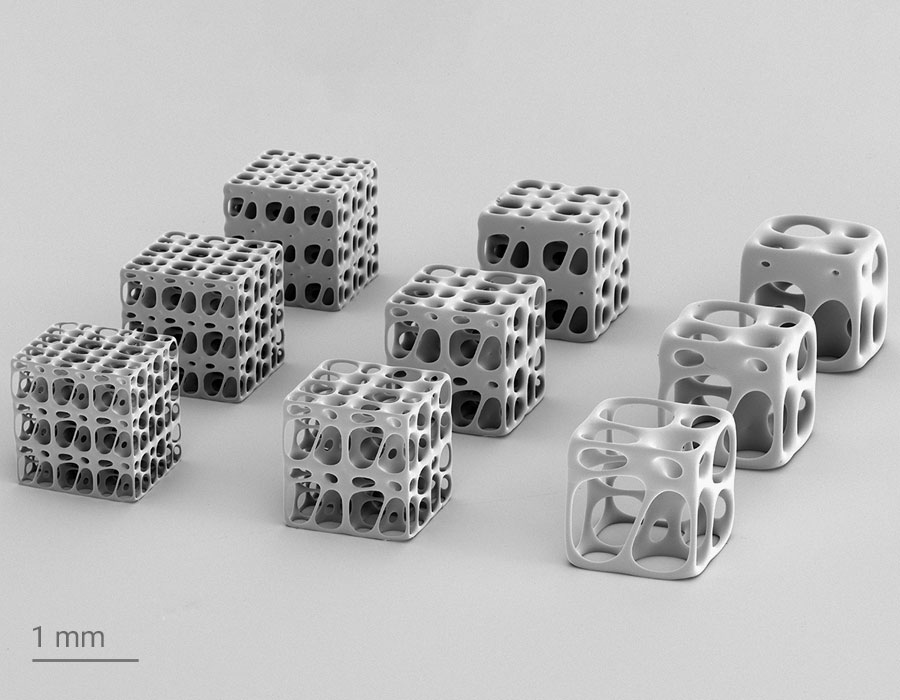

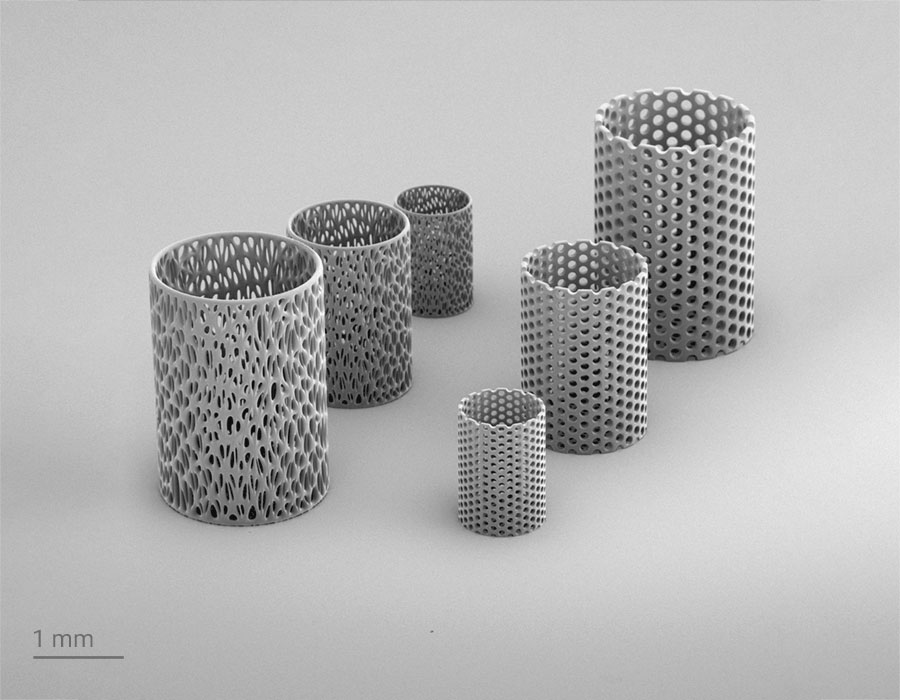

With Quantum X bio, we’re bringing the next level of 3D bioprinting

across all scales, from the subcellular to millimeters; whether printing’ on cell culture dishes, microscope slides or directly inside microfluidic chips. Hard acrylates, soft synthetics, natural bioresins and custom photoresins. The world is your playground across all dimensions.

Optimized for cellular printing

A temperature-controlled environment in conjunction with onboard sterility measures makes the Quantum X bio the go-to system for exploring biological applications.

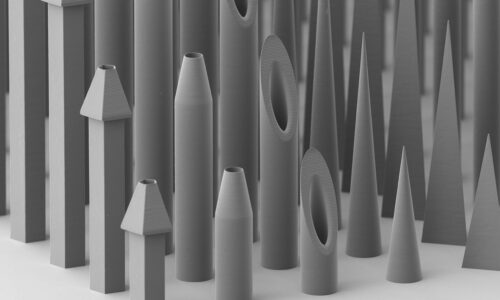

2PP brings unprecedented accuracy

A flexible and intuitive software solution

Sensors and video to keep quality on lock

Extensive biomaterial offerings

Choose between our functionalized biomaterials developed at Nanoscribe, CELLINK and Advanced BioMatrix, or from externally available photoresins.

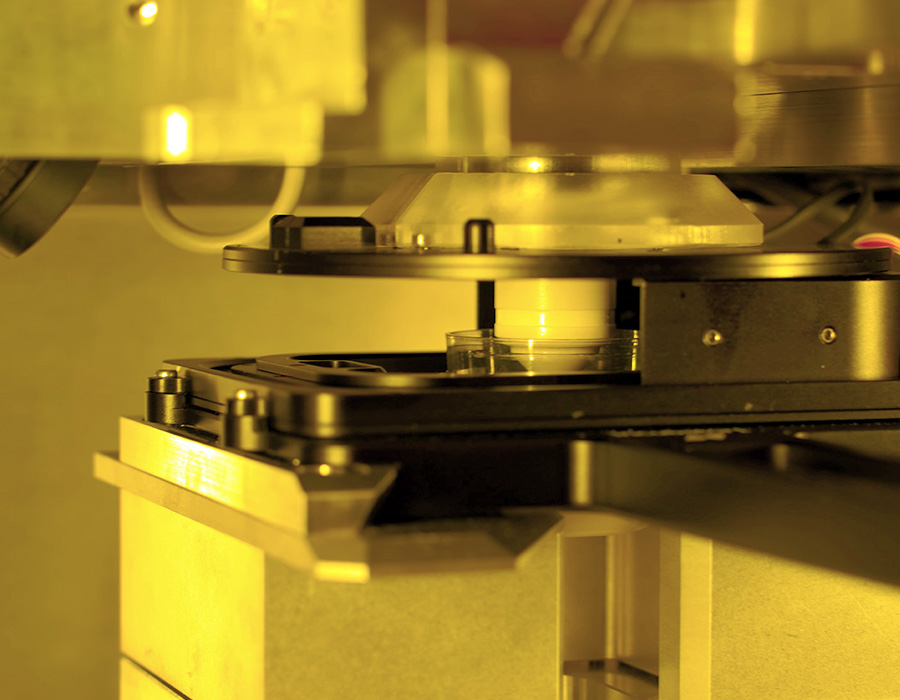

Game-changing bioprinting chamber

The chamber creates temperature and humidity controlled conditions, and a HEPA-filtered airflow with optional connections for pre-mixed air/CO2.

In-chip printing

MICROFLUIDICS MEET CELL CULTURE

Quantum X bio is a powerful 3D Microfabrication system that provides the flexibility and capabilities to print on a variety of substrates, including microfluidic systems for organ- or lab-on-a-chip applications. With these capabilities, microfluidics meets cell culture, enabling the creation of organoids.

- Printing into microfluidic systems, including custom microfluidic channels and commercial microfluidic chips

- Enabled by Dip-in Laser Lithography (DiLL)

- Highly precise positioning of the prints within microfluidic systems

- High aspect ratio and high structures can be printed into open microfluidic channels and wells

- Touchscreen tap-to-align feature to easily set the print position within the channel or well

- Open system for custom resins, such as degradable materials

- Standard 3D designs available in Bioprinting Model Library

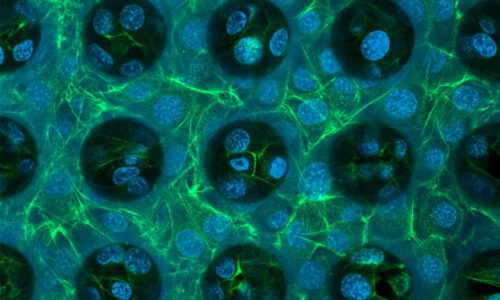

Be prepared for live-cell printing

- Open system compatible with any available bioresin

- Cell-friendly wavelength (780 nm)

- Sterile, temperature-controlled environment

- Cell viability >90% possible

Cultivate cells in 3D

3D printed drug delivery

And more applications

- Cell Scaffolds

- Microtissues

- Living/4D materials

- Microfluidics

- Microneedle arrays

- Drug delivery vectors

- Micro/soft robotics

- Vascular models

- Topology for cell mechanics and migration

- Biosensors

- Materials engineering

What is 2PP bioprinting?

SOFTWARE

Ready. Set. Print.

Organize and monitor your research project with our intuitive software and excellent data tracking. Generate, upload, print, and monitor your print job directly from the device’s touchscreen or remotely from your PC.

With Nanoscribe’s UX-optimized software solutions, inspired by a bioprinting library of proven STL models, and monitoring of sensor and video data during printing, it’s genuinely easy to achieve printing success.

Technical Specifications

| Minimum feature size¹ | down to 100 nm |

| Stitching-free part diameter | up to 4000 µm |

| Live-cell printing viability | > 90% |

| Maximum scan speed² | 6.25 m/s divided by lens magnification |

GENERAL SYSTEM PROPERTIES

| Printing technology | Layer-by-layer 3D printing based on Two-Photon Polymerization (2PP) Upright platform with Dip-in Laser Lithography (DiLL) |

| Substrates | Microscope slides / microfluidic chips (3 x 1” / 76 x 26 mm)

Wafers 1” (25.4 mm) to 6” (150 mm) Glass, silicon, and further transparent and opaque materials, and coated/uncoated substrates Cell culture imaging dishes (35 mm or 50 mm) |

| Photoresins | Open system for custom materials

Hydrogels/Bioresins from Advanced BioMatrix, CELLINK and BIO INX Nanoscribe IP/IPX Photoresins (polymers) Nanoscribe acrylate, PDMS and glass photoresins (biocompatible, ISO 10993-5) |

| Maximum printing area | 50 x 50 mm² |

Given values may vary depending on the photoresin and structure geometry

¹ 100 nm feature size control in x/y direction, valid only for certain photopolymers

² e.g. for 10x magnification: 625 mm/s

Bioconvergence at its best

Powered by NANOSCRIBE’s proprietary Two-Photon Grayscale Lithography (2GL®) technology and CELLINK’s award-winning cell-friendly technologies, the Quantum X bio high-precision 3D microfabrication bioprinter is the first of its kind. 2GL has been customized and reimagined with the cell biologist and tissue engineer in mind. Microfabrication speed and precision meet patented Clean Chamber sterilization, advanced temperature controls and biocompatibility to create the fastest and most precise tool on the market for vasculature printing with excellent shape accuracy.

The Quantum X bio promises to accelerate innovation across critical applications like tissue engineering, cell biology and regenerative medicine.