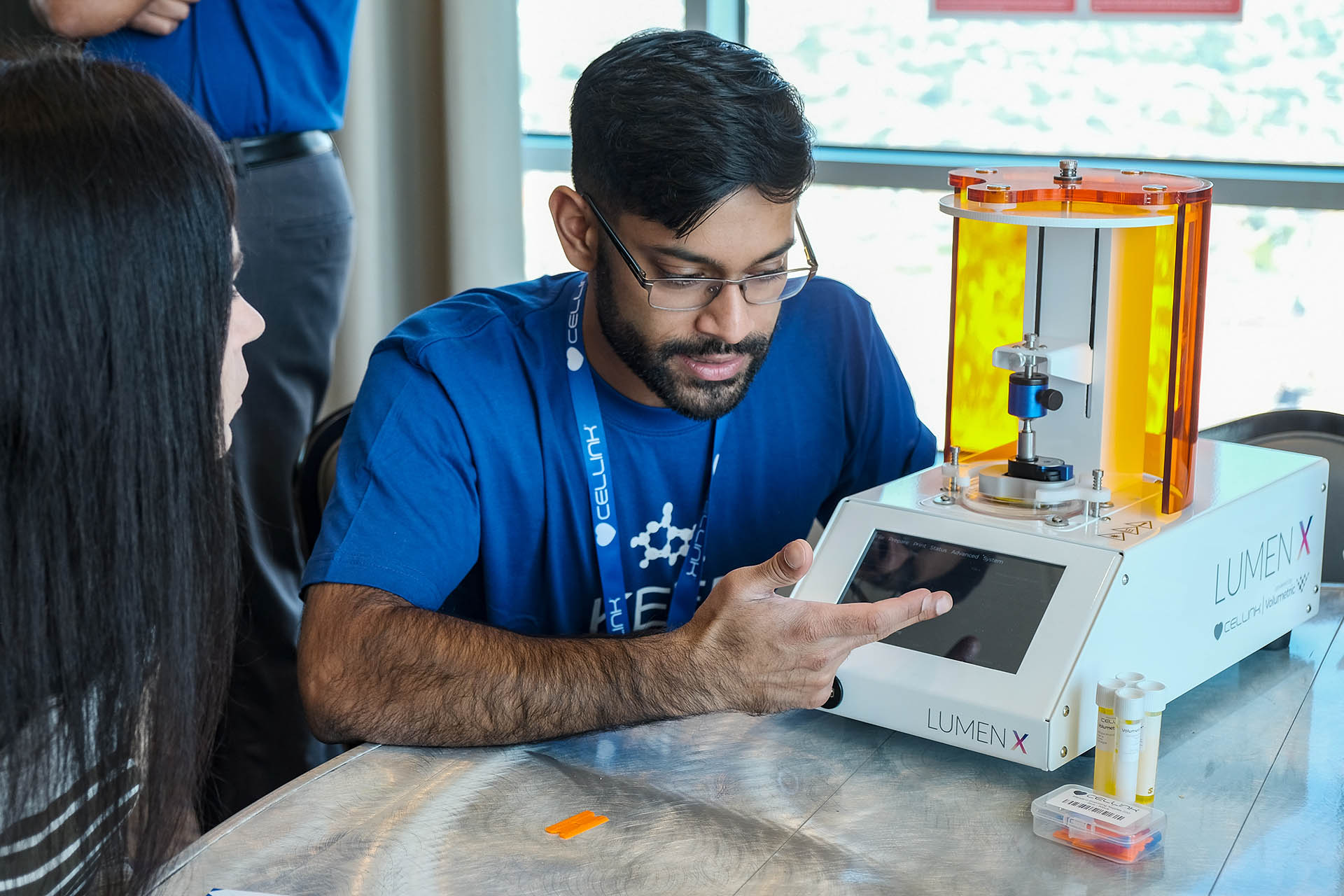

Interviewing a CELLINK engineer on the future of bioprinting

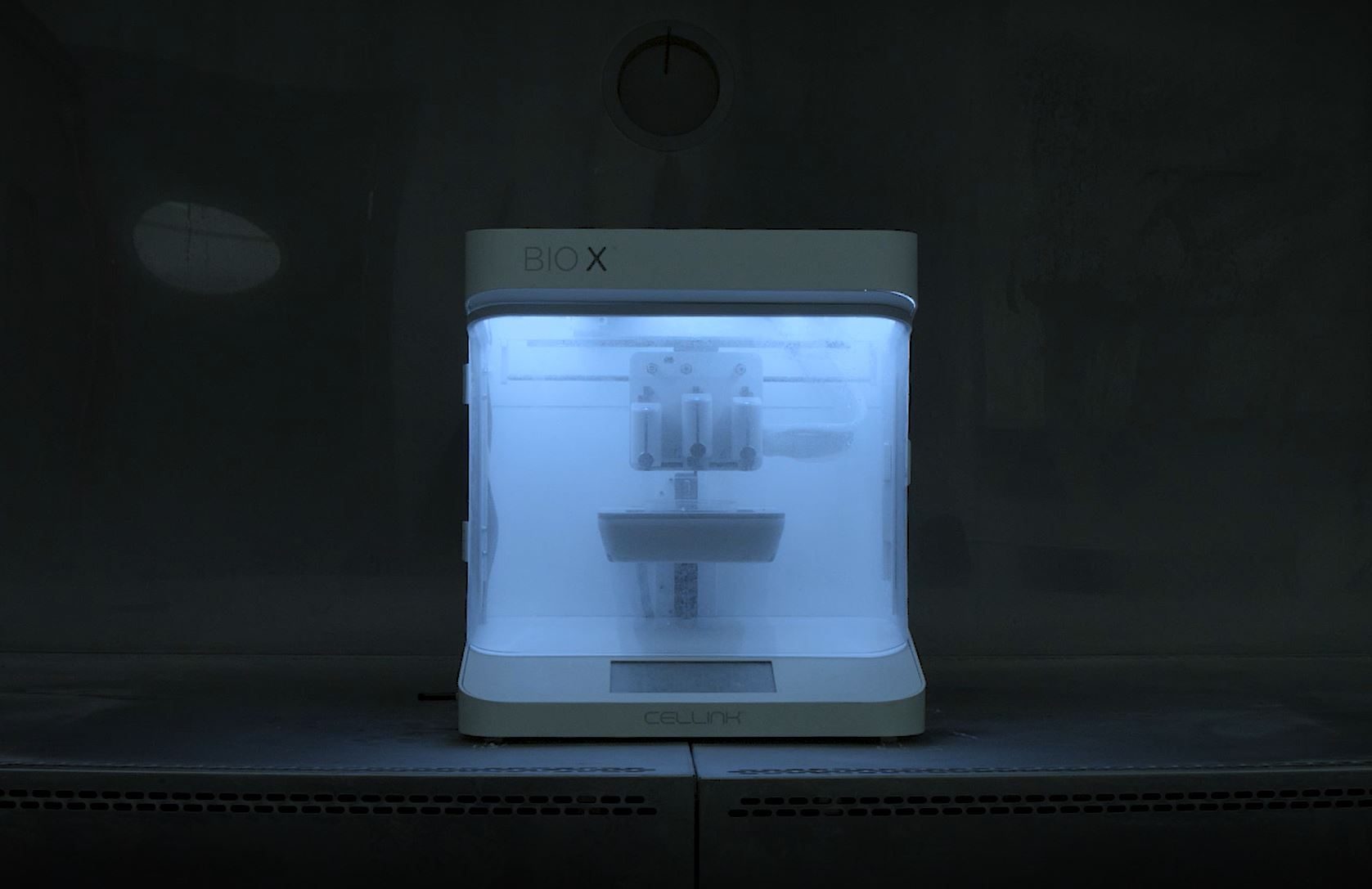

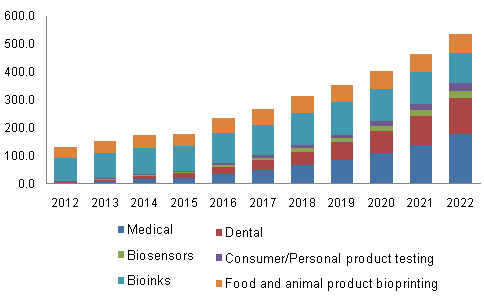

The first bioprinter was made in 2003 and the field of bioprinting has been growing rapidly ever since – it’s expected to reach a market size worth more than $4 billion by 2026.

Will full organs be printed soon?

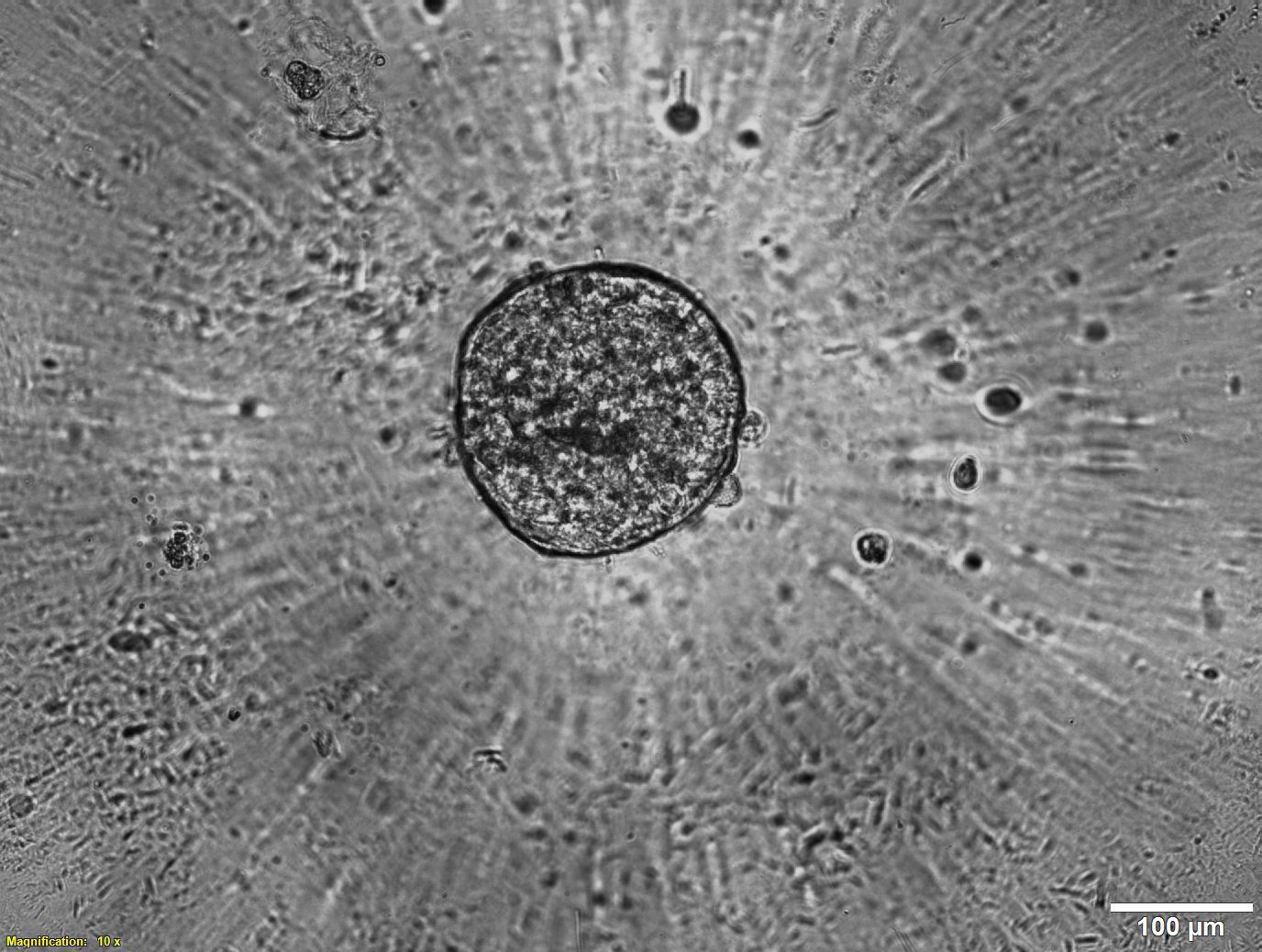

Rahul Roy: Soon is relative. Organs will be printed with ten years in research, but certainly not for clinical use within that time. Part of the problem is figuring out how to turn biomaterials into tissue, and the fact that it’s very expensive to do so because of the cell investment. Even tiny millimeter cubes could cost thousands of dollars.

The challenges are still, how do we accurately and effectively create tissue that mimics what we have in our bodies? And regarding the price, as with any technology, people are learning new ways to make cell manufacturing more cost-effective.

Could AI help us copy the structures of the brain and the body?

RR: AI will certainly have a role in the future of bioprinting.

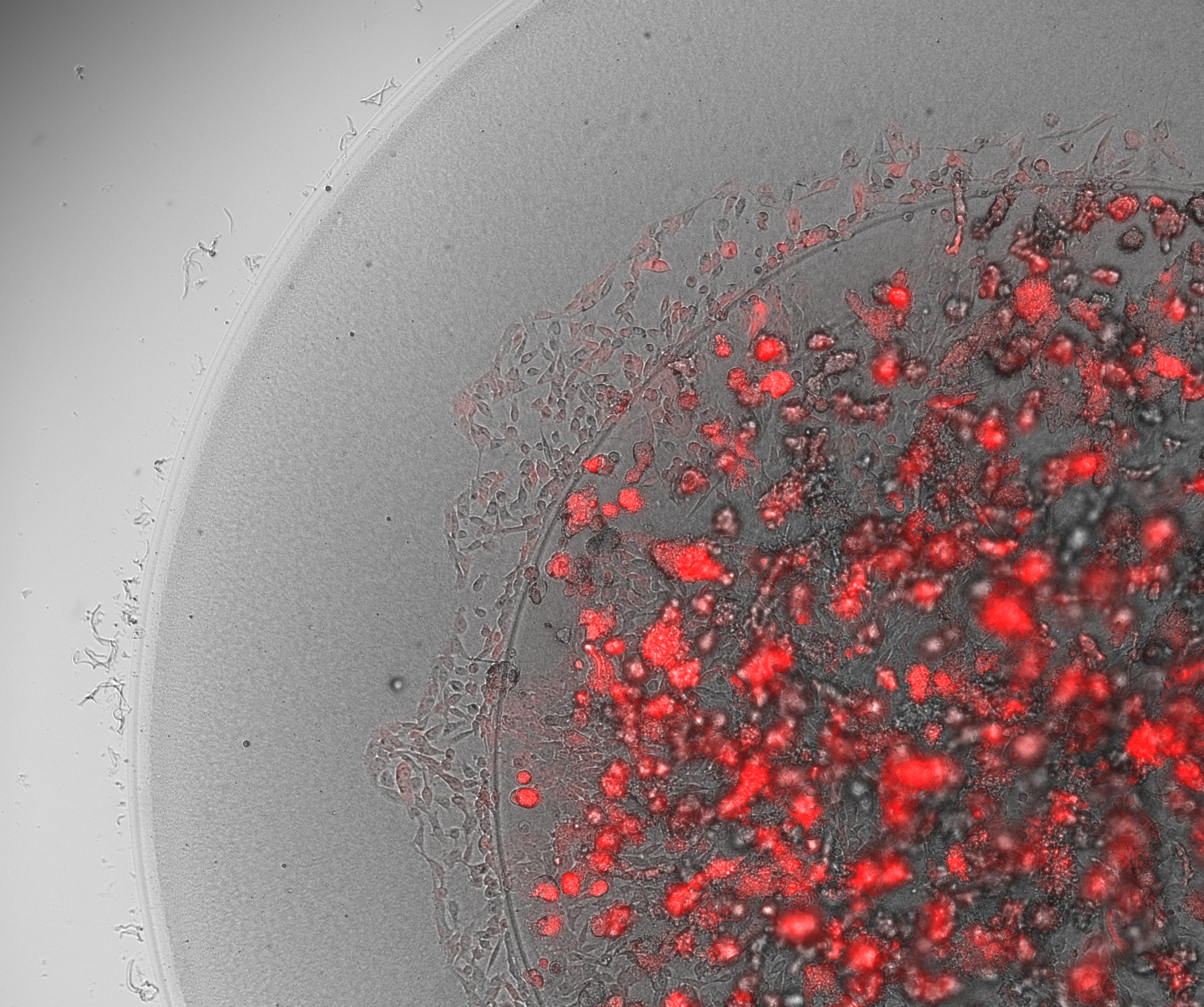

We need to understand how scaffolds receive signals from the body and how the materials in a scaffold transform into tissues. That’s the core of tissue engineering – learning how to transform scaffold into tissue. There are a number of factors involved that make it hard to understand that relationship. AI will help us understand these patterns and relationships more accurately.

In the clinic, we could use AI to examine a patient, understand their tissue and create the right recipe of biomaterials and geometry to ensure the scaffold works well in the body and develops correctly.

Will bioprinting create a sustainable meat alternative?

RR: Without a doubt! It will be integral in understanding how we can grow convincing and tasty meat. The challenges that are involved in understanding how our muscles develop will be important in understanding how we make different cuts of steak.

Could bioprinting make vegan leather or alligator skin?

RR: Yes, absolutely. That’s a really challenging thing, creating the texture of alligator skin – it might synthesize many different technologies – but bioprinting could certainly contribute. Leather might be easier. It could be accomplished with bioprinted skin and traditional tanning techniques.

Finally, when it comes to the future of bioprinting, what are you the most hopeful for?

RR: I’m hopeful for the therapies that will cure diseases – Alzheimer’s, Parkinson’s, cancer – things that we consider incurable. I’m excited for those to be treatable. Being able to provide a research tool for these application areas is exciting.

While there are a lot of questions in this pioneering field, one thing is clear: bioprinting will change the definition of what’s possible across multiple industries. Its applications in organ generation, food sustainability and disease treatment will bring new tools to researchers and new aid to large groups of people.