The Ultimate User Guide to Bioprinting Neural Tissue

Whether you are new to bioprinting or a first-time BIO X user, the recently published “Protocol for Printing 3D Neural Tissues Using the BIO X Equipped with a Pneumatic Printhead” is a must-read.

The Willerth Laboratory, headed by Stephanie Willerth, PhD, a 12-year veteran at the University of Victoria who recently finished a 3 year term as the director of biomedical engineering, has earned a reputation for training highly qualified researchers, from post-doc fellows to interdisciplinary graduate and undergraduate students, as well as developing novel tools that help advance tissue engineering and regenerative medicine, including Axolotl Biosciences’ fibrin-based bioink.

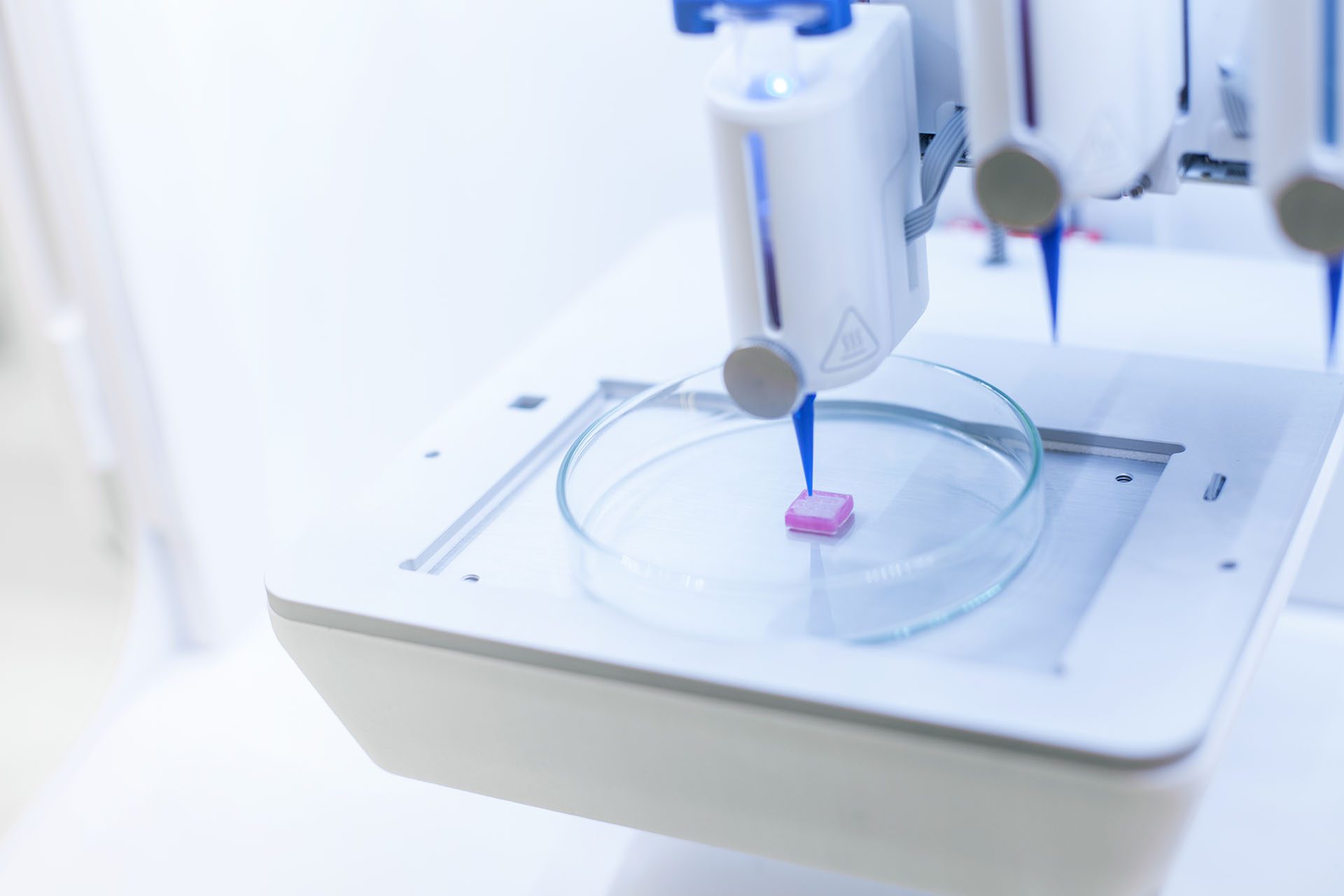

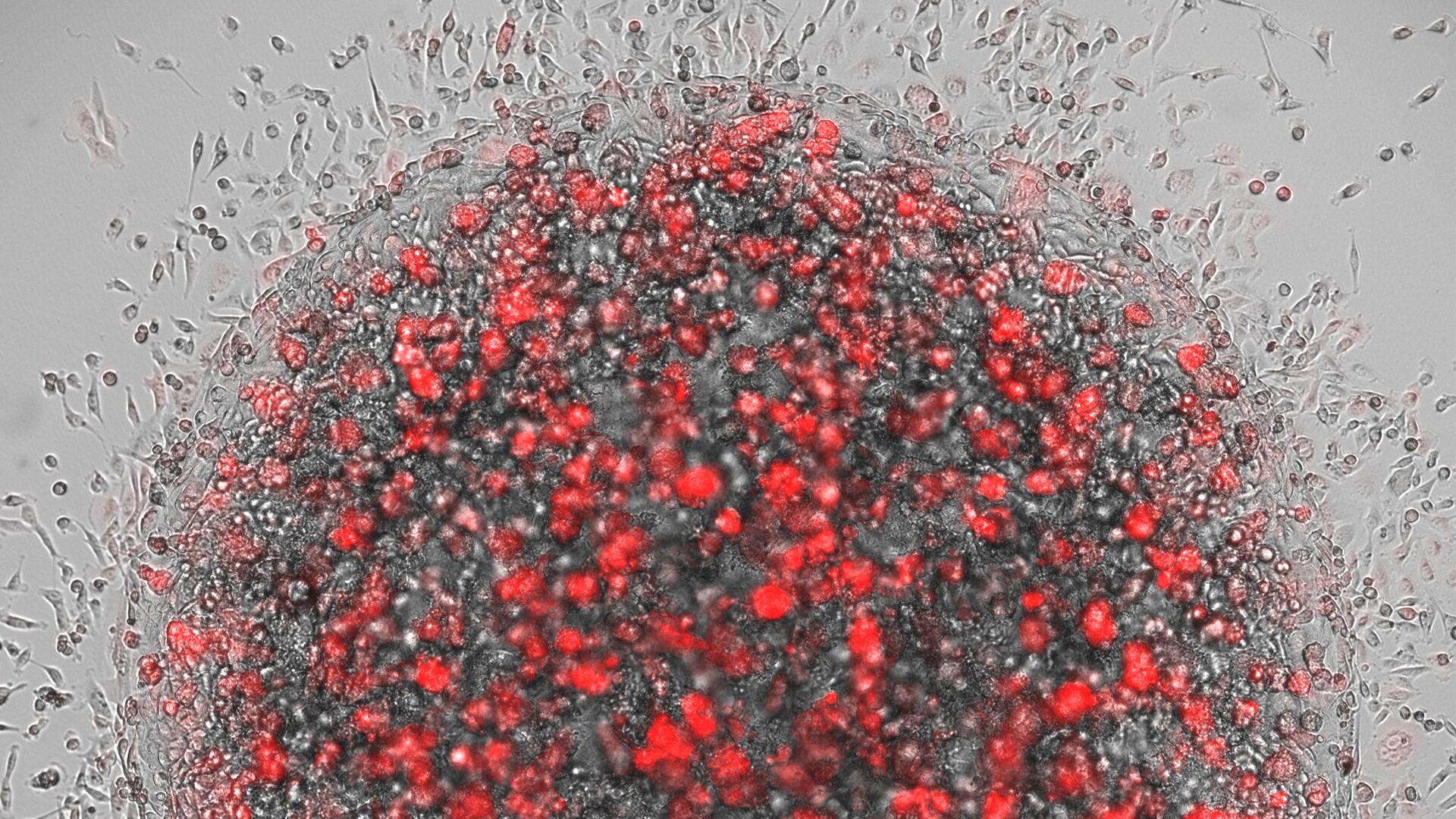

Josie Chrenek, an undergraduate researcher in the lab, co-authored a step-by-step protocol in the peer-reviewed Star Protocols for 3D bioprinting neural tissue with the extrusion-based BIO X™ bioprinter. The protocol covers how to load consumables, mount cartridges to printheads, and set printing parameters to produce high-quality 3D biological constructs. Readers can expect the resulting constructs to ensure the highest levels of cell viability during culturing for up to 6 weeks in a 37°C incubator with regular media changes.

Bioprinting 101 in a PDF

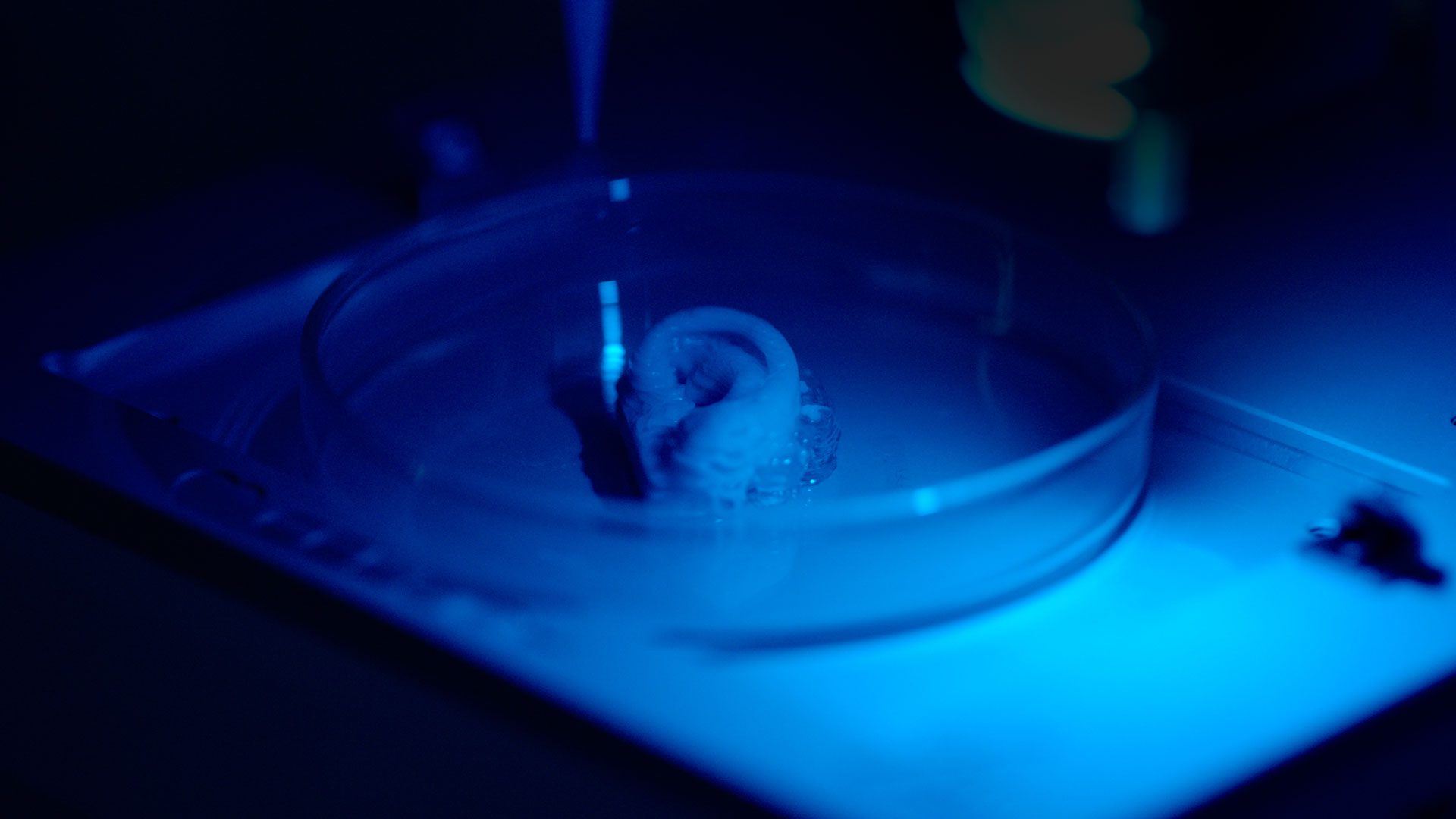

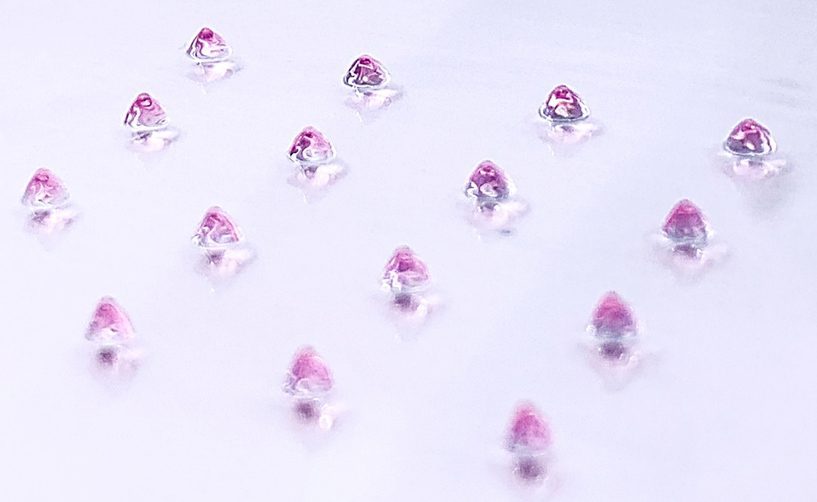

The protocol’s detailed instructions take the user through prepping reagents, sterilizing equipment, printing into a standard culture dish or an agarose bath, and even culturing the resulting constructs. It reads as clearly as a how-to recipe from your favorite cooking channel. Dr. Willerth’s team included specifics such as the amount of crosslinker needed per milliliter of bioink, estimated time to complete each step, recommended temperature settings for stir plates, and the approximate number of constructs it will yield. Bonus? They labeled individual consumables by name in photographs of needed equipment.

One multimedia section of interest covers setting up the BIO X bioprinter, from loading syringes with cell-laden bioink (helpful how-to video included) to mounting cartridges on printheads. This section guides the user through the bioprinter’s intuitively designed touchscreen interface, from which the user can load computer-aided design (CAD) files, select the appropriate bioink profile, calibrate the nozzle tip, as well as set desired pressure, printing speed and infill density.

Throughout this essential primer, critical notes highlight precautions to keep in mind. One note explains why the user should combine bioink components right before printing to avoid flocculation and the formation of fibrin discs. Another note about the BIO X’s patented Clean Chamber technology, reminds the user to close the BIO X’s protective door that blocks UV light.

More helpful features

Easy-to-read tables serve as quick reference guides for recommended printing parameters if, for example, printing into a cell culture plate or an agarose support bath. While others list the equipment and consumables needed to set up a print: biomaterials, reagents, cell lines, consumables (product numbers and supplier websites included). There is also a user-friendly troubleshooting guide that offers 3 or 4 potential solutions for everything from air bubbles in the bioink to leaky nozzle tips. Lastly, just as the versatile BIO X bioprinter is universally compatible with any biomaterial, the protocol can be adapted to any cell line compatible with extrusion-based bioinks that require crosslinking.

This open access handbook is must-read for everyone, from undergraduate students to established professionals who need a cheat sheet on setting parameters. Available for download here.