Creating More Complex Constructs with Coaxial Bioprinting

Introduction to coaxial bioprinting

Requirements for coaxial bioprinting

Applications for Coaxial Bioprinting

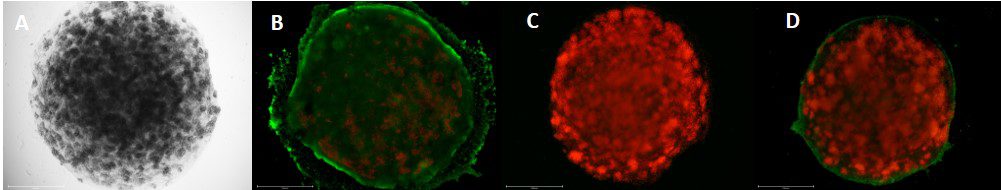

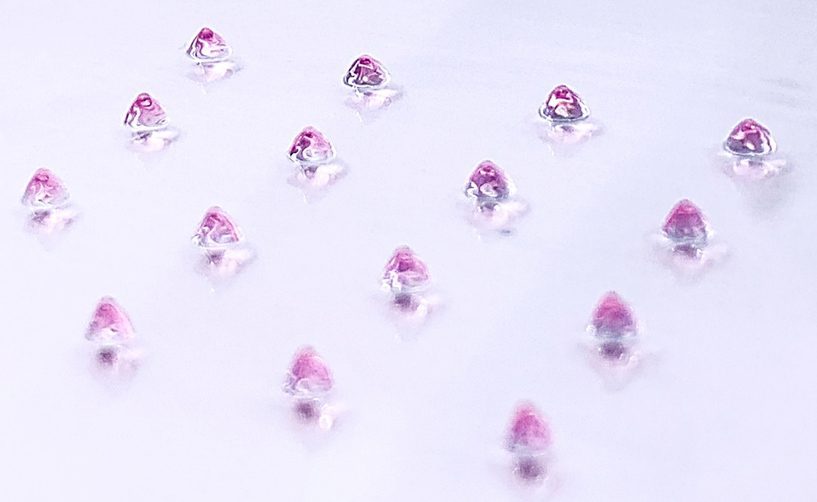

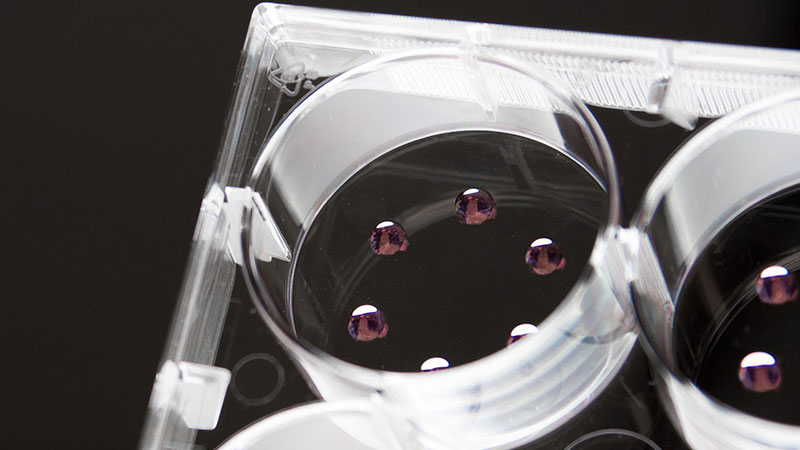

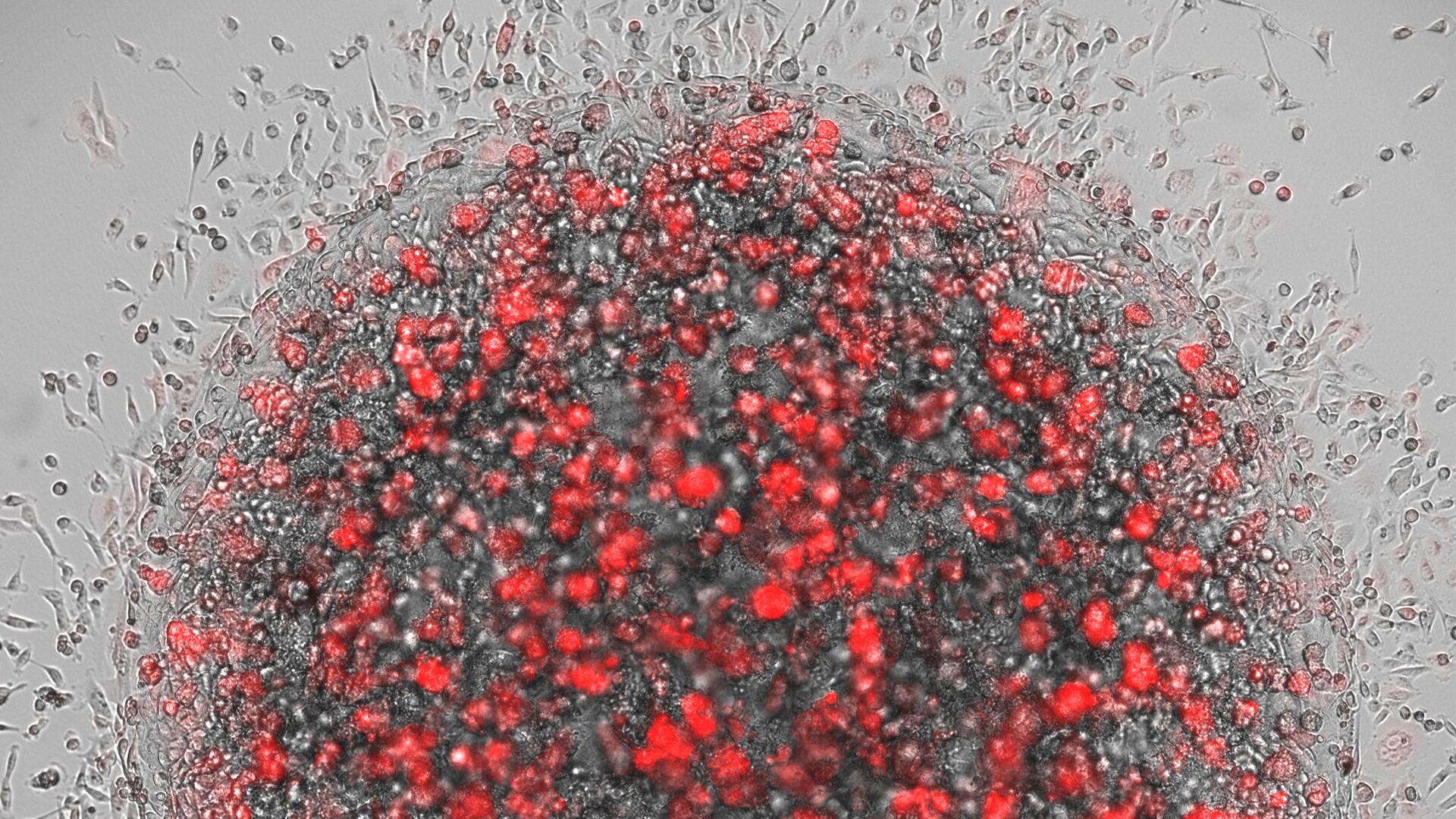

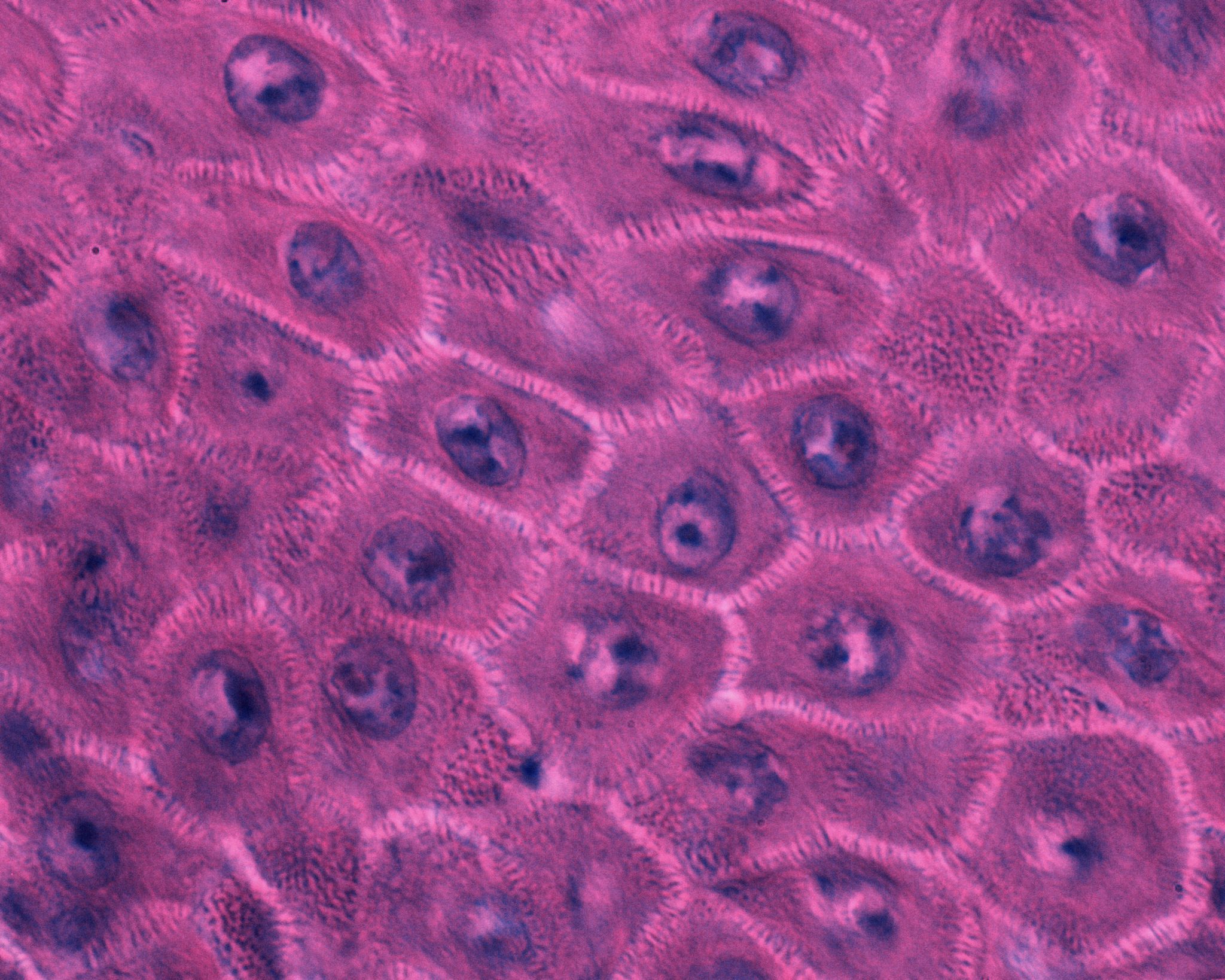

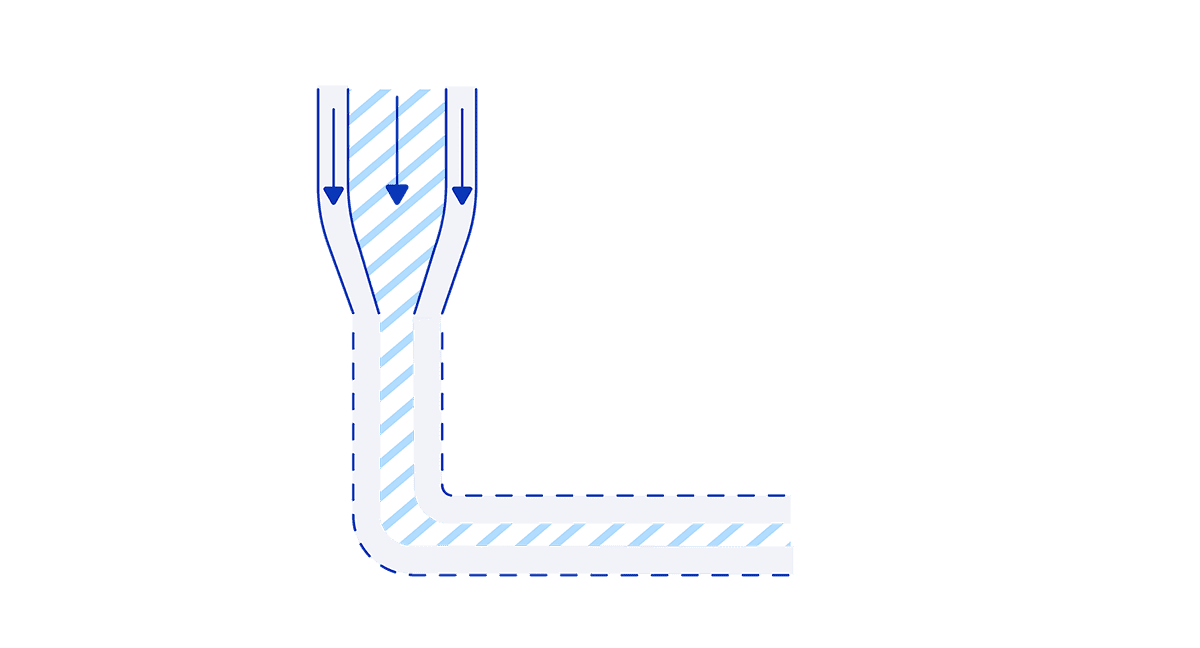

Additionally, coaxial extrusion can be used to perform in situ crosslinking in order to enable the extrusion of otherwise unprintable biomaterials such as alginates. One way to create tubular structures is by printing a single or multilayer hydrogel sheath out of an alginate-based material with a CaCl2 crosslinking solution core. In a simpler application, the technique can be used for the fabrication of smaller models such as spheroids and organoids by depositing droplets comprised of two or more layered biomaterials or cell types.

Best Practices When Doing Coaxial Bioprinting

Retest your bioinks before printing

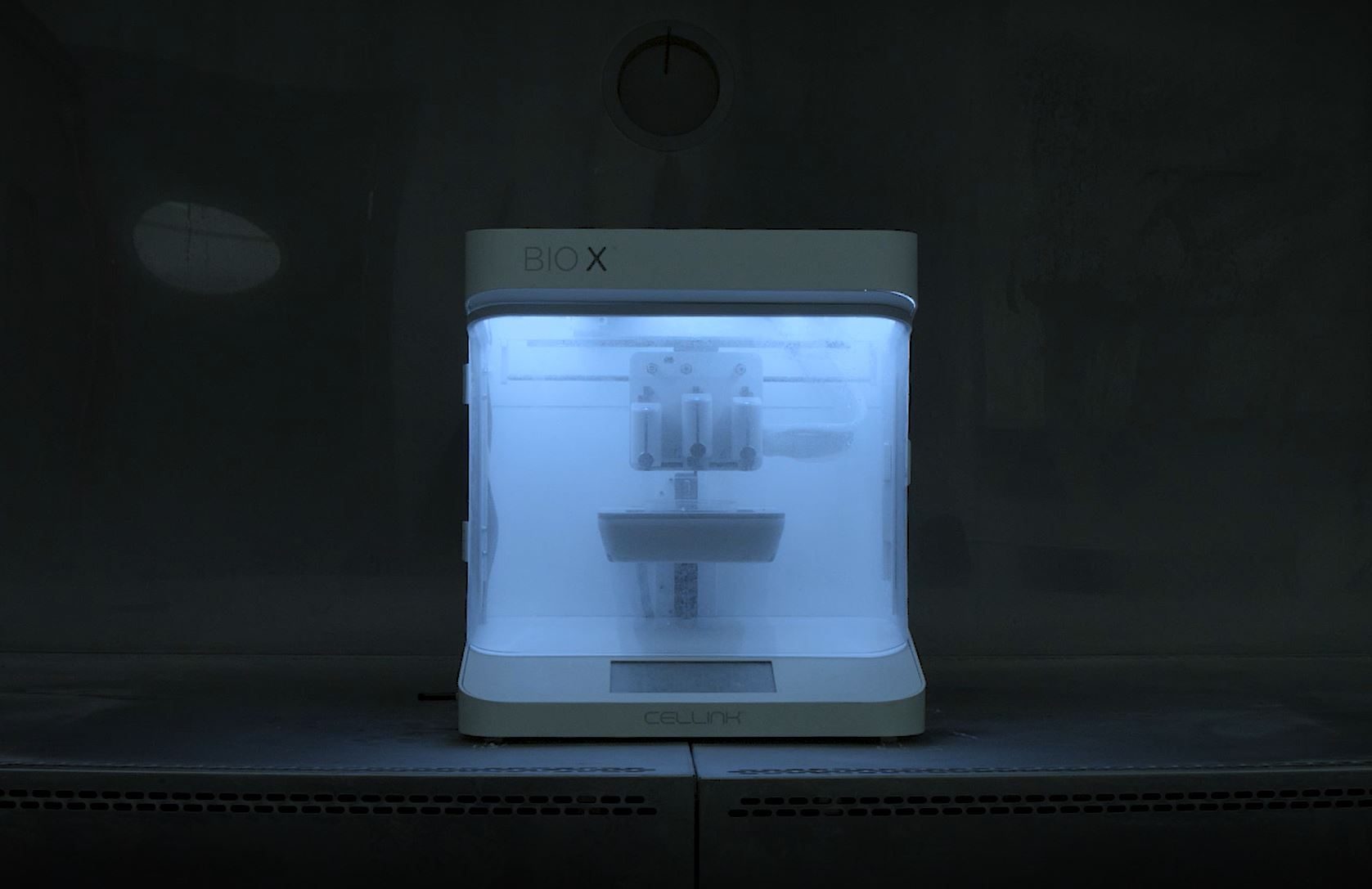

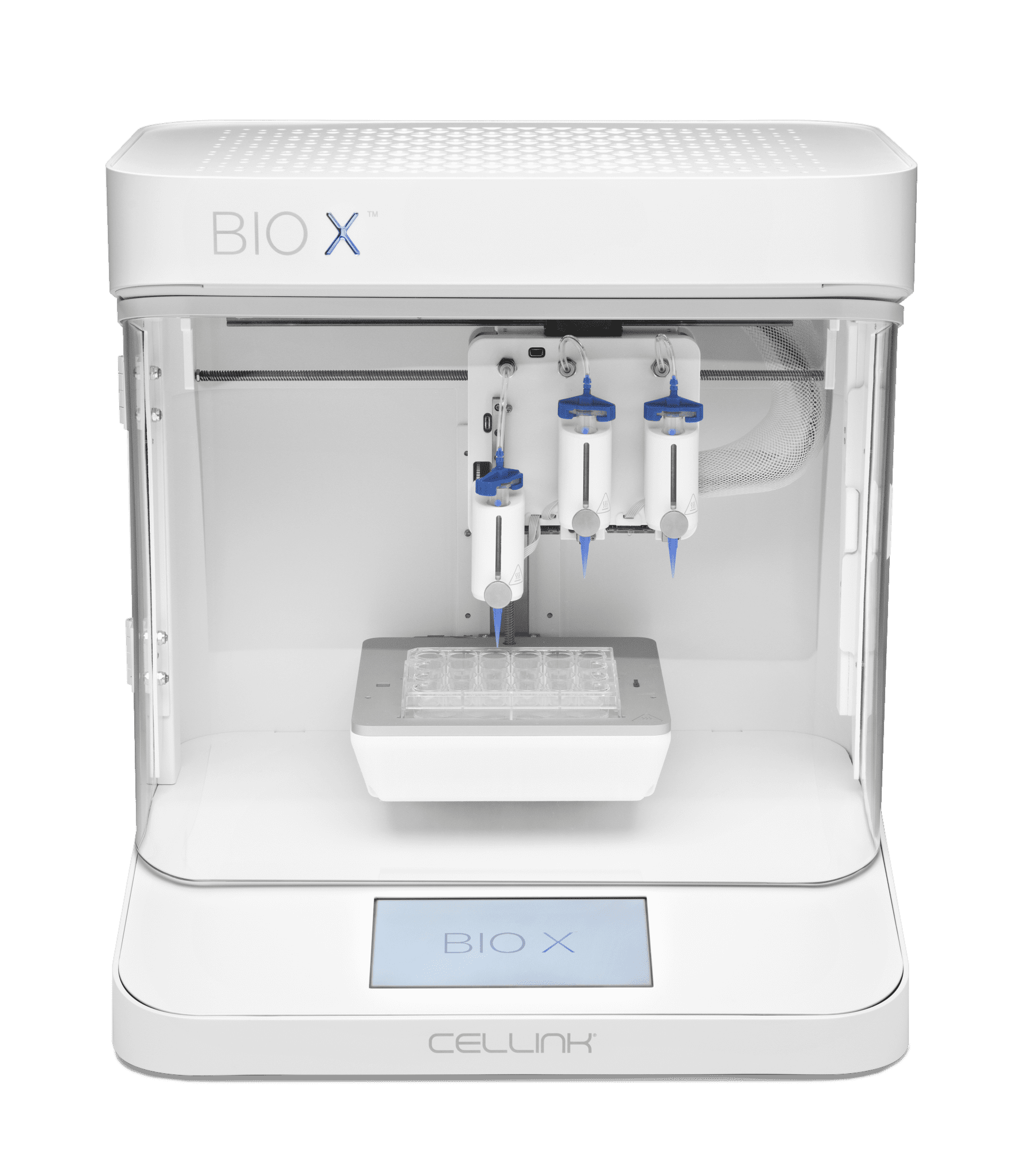

When using coaxial bioprinting, one must consider the narrower range of bioinks that are compatible with the confined geometry of a coaxial needle. It is often advantageous and necessary to retest bioinks for coaxial bioprinting, although the bioinks are already being used for traditional bioprinting. This can often be done by using needle lengths and gauges that match the coaxial needle setup that one intends to use (e.g, 0.5-inch length and pressures below 200 kPa). For the extrusion of biomaterials requiring over 200 kPa, an external pump can be connected to the bioprinter to reach a pressure up to 700 kPa.