Printing dual droplets

Here at CELLINK, we want to inspire you to print more advanced models using the BIO X. In the following section, we demonstrate dual droplet printing with two of our bioinks.

Products used:

Video demonstration

In this video, we demonstrate printing droplets side by side using a pneumatic printhead for CELLINK Bioink and a Temperature controlled printhead with nozzle insulator for GelMA A. Both CELLINK Bioink and GelMA A were diluted with 10% cell suspension and the cartidges were capped with 25G nozzles. Different bioink droplets were printed beside each other on a 12-well plate lid. CELLINK Bioink was printed at 15-20 kPa, while GelMA A required higher pressure of 35-40 kPa. Despite the different properties of CELLINK Bioink and GelMA A, both bioinks can be printed in the same printing session beside each other. Both CELLINK Bioink and GelMA A droplets can be crosslinked by adding our crosslinking agent. Additionally, GelMA A droplets also have the ability to be photocrosslinked.

The G-code for printing these dual droplets can be found on Bioverse. The distance between the droplets can be changed in the G-code from 4 mm to any distance preferred.

Individual printhead control for simultaneous bioprinting

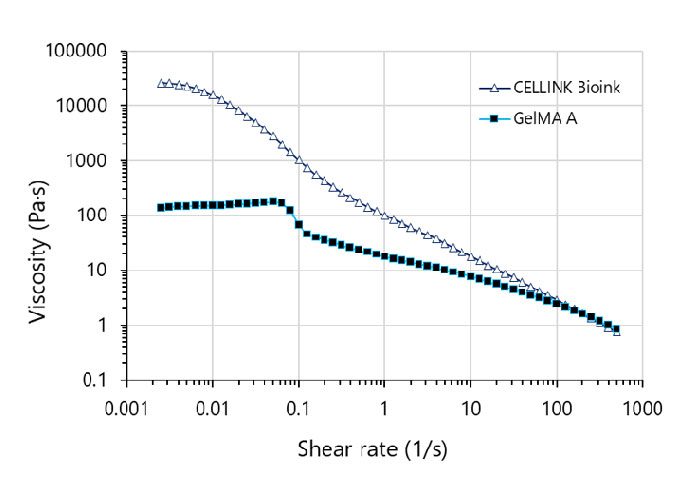

Figure 1. Viscosity dependence on shear rate for CELLINK Bioink and GelMA A

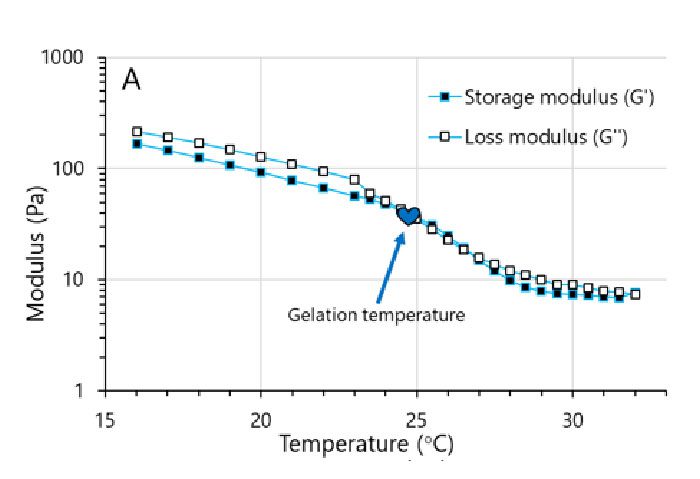

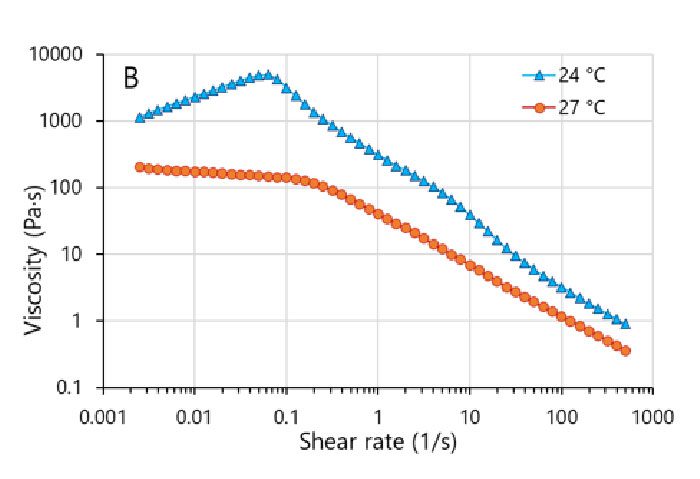

Set the right temperature

Figure 2. A) Temperature sweep for GelMA A. B) Viscosity dependence on shear rate for GelMA A measured at the temperatures above (27°C) and below (24°C) gelation temperature.

Multicellular tissue models