Mass-Produced Stem Cells: A Gateway to Personalized Medicine

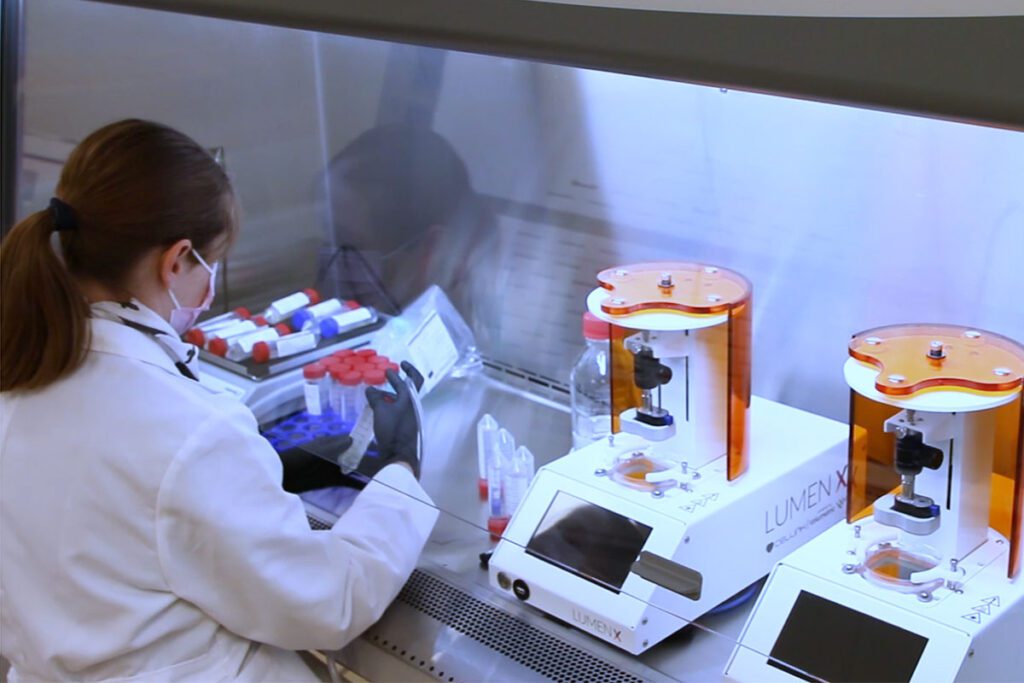

Ronawk, a Kansas-based bioengineering firm founded by A.J. Mellott, PhD, and Heather Decker, is revolutionizing regenerative medicine with the T-block, an innovative hydrogel scaffold that facilitates mass producing adult stem cells. The startup’s chief executive officer, Dr. Mellott, says that CELLINK’s renowned team of application scientists supported him from beginning to end. They helped as he perfected his 3D bioprinted prototype on the BIO X™ all the way to manufacturing it in high throughputs on the LUMEN X™ DLP bioprinter.

Watch the 3D bioprinting of T-blocks

The study of adult stem cells has increased exponentially because of recent technological innovations in the life sciences, especially within the field of bioprinting. The array of applications under consideration runs the gamut—from reversing baldness to managing diabetes to transplanting personalized 3D bioprinted organoids. With the latter, researchers are envisioning culturing a patient’s adult stem cells to create viable organoids that could be transplanted with no need for long-term immunosuppressant drugs.

One of the obstacles that has stymied stem cell researchers is how difficult locating adult stem cells in bone marrow, brain, muscle or fat tissue can be. Not to mention, extracting them in the quantities realistically needed for clinical use is very time-consuming. As a result, many researchers have been looking to generate adult stem cells in mass quantities with in vitro cell culturing.

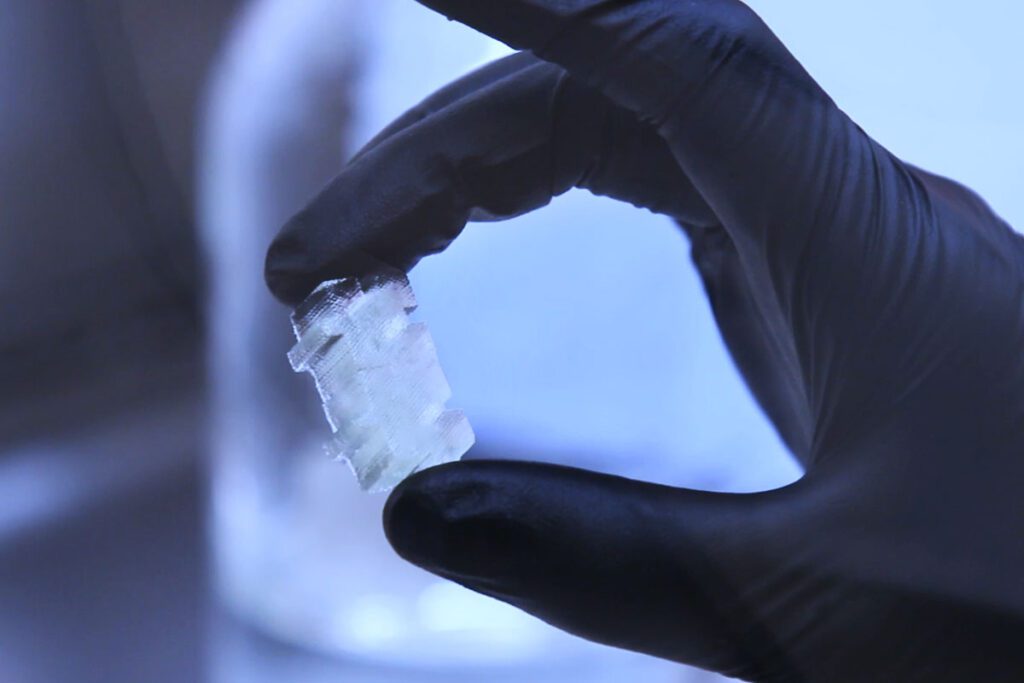

Enter Ronawk’s T-block, a 3D bioprinted scaffold for stem cell production

The startup, which was spun off from labs at the University of Kansas Medical Center, used biocompatible hydrogels and a unique geometry to design the interlocking 3D bioprinted scaffolds. They then seed the T-block constructs with the adult stem cells, giving them the proper environment to proliferate in vitro in greater numbers. Keeping extracted adult stem cells viable for long periods of time was another roadblock to working the adult stem cells. However, with Ronawk’s modular design, additional bioprinted T-block scaffolds can be added in the X, Y, Z axial directions indefinitely. Because there is no need for passaging, stem cells are free to continue proliferating, migrating, secreting extracellular matrices and maturing into tissue.

Dr. Mellott characterizes the relationship with CELLINK less like one of traditional customer support and more of a collaboration. While experimenting with prototypes on the BIO X, he says, the suggestion from the company’s application scientists to experiment with options from the wide array of interchangeable printheads and toolheads was invaluable. Then, he was introduced to the digital light processing (DLP) LUMEN X 3D bioprinter, which allowed them to ramp up production on a much larger scale and with more precision. Furthermore, after the Kansas lab customized a platform to accommodate the extra printing area needed for the T-blocks, it was the CELLINK team who devised a workaround for handling the bigger files.

According to Decker, Ronawk’s chief technical officer, CELLINK’s assistance helped significantly accelerate the production timeline for their stem cell scaffold. “We can now control the resolution and multiple aspects of the T-block that previously we had very little control over,” she says, crediting these workflow optimizations, among others, with shortening the cumbersome production process from several weeks to 3 days. But Paul Berning, head of global sales at CELLINK, insists that the relationship is symbiotic, “Ronawk also offered us valuable feedback on biomaterials, and we look forward to more collaborations.”