Bioprint like a pro

Printing pressure

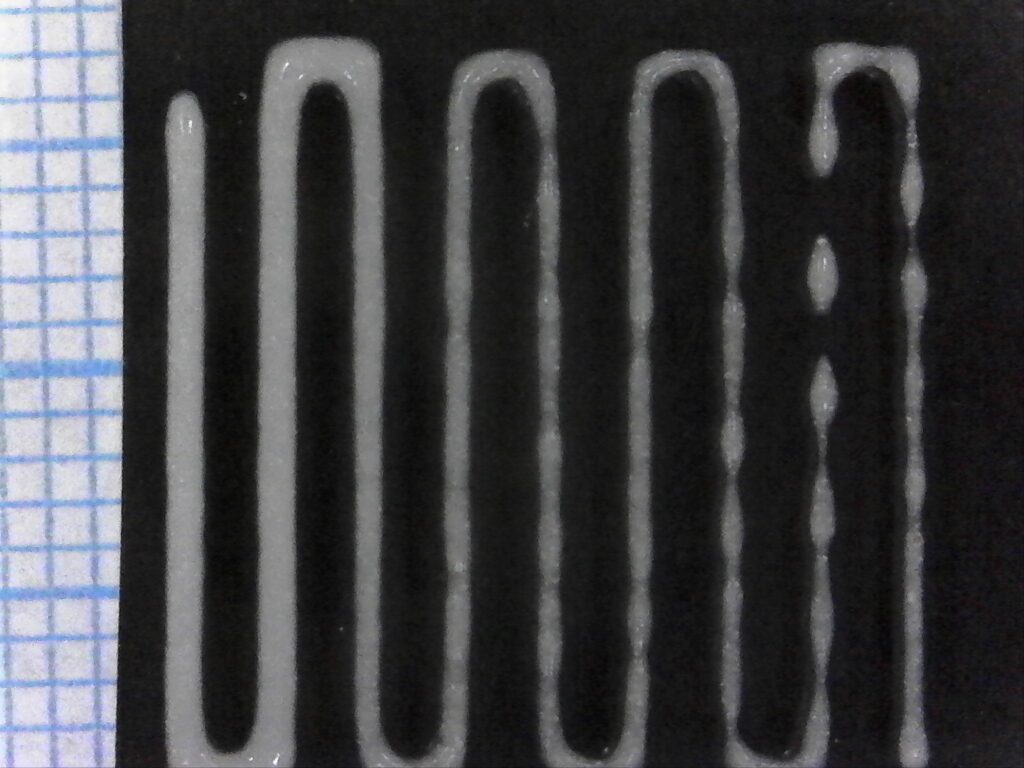

On this page, we’ll do a deep dive into the effects of pressure on a bioprinted construct. Extrusion-based bioprinting generates pressure in a cartridge to force a bioink to flow through a nozzle. Changing the amount of applied pressure changes the bioink’s flow rate, which can drastically change the resulting bioprinted construct. Pressure is just one parameter out of many to consider when bioprinting, including print speed, temperature, nozzle size and more.

Pneumatic printhead

Syringe printhead

Pressure is key

Fast vs. slow

For materials with poor structural integrity before crosslinking, users can use higher pressures to print more rapidly and crosslink before the construct begins to collapse. At higher pressures, you can increase the nozzle’s translation rate along the printbed – even though more bioink is coming out more quickly, the nozzle covers more ground, depositing the same amount of bioink per length unit of the filament. Users can max out these parameters to print a construct as rapidly as possible.

At the same time, the lowest pressure possible is not necessarily the best for printing with cells. Some bioinks require that cells be outside of incubator conditions for 15-20 minutes, and using slightly higher pressures enables users to select higher speeds, finish faster and reduce the time spent outside of the incubator.