3D Bioprinters

Extrusion 3D bioprinting

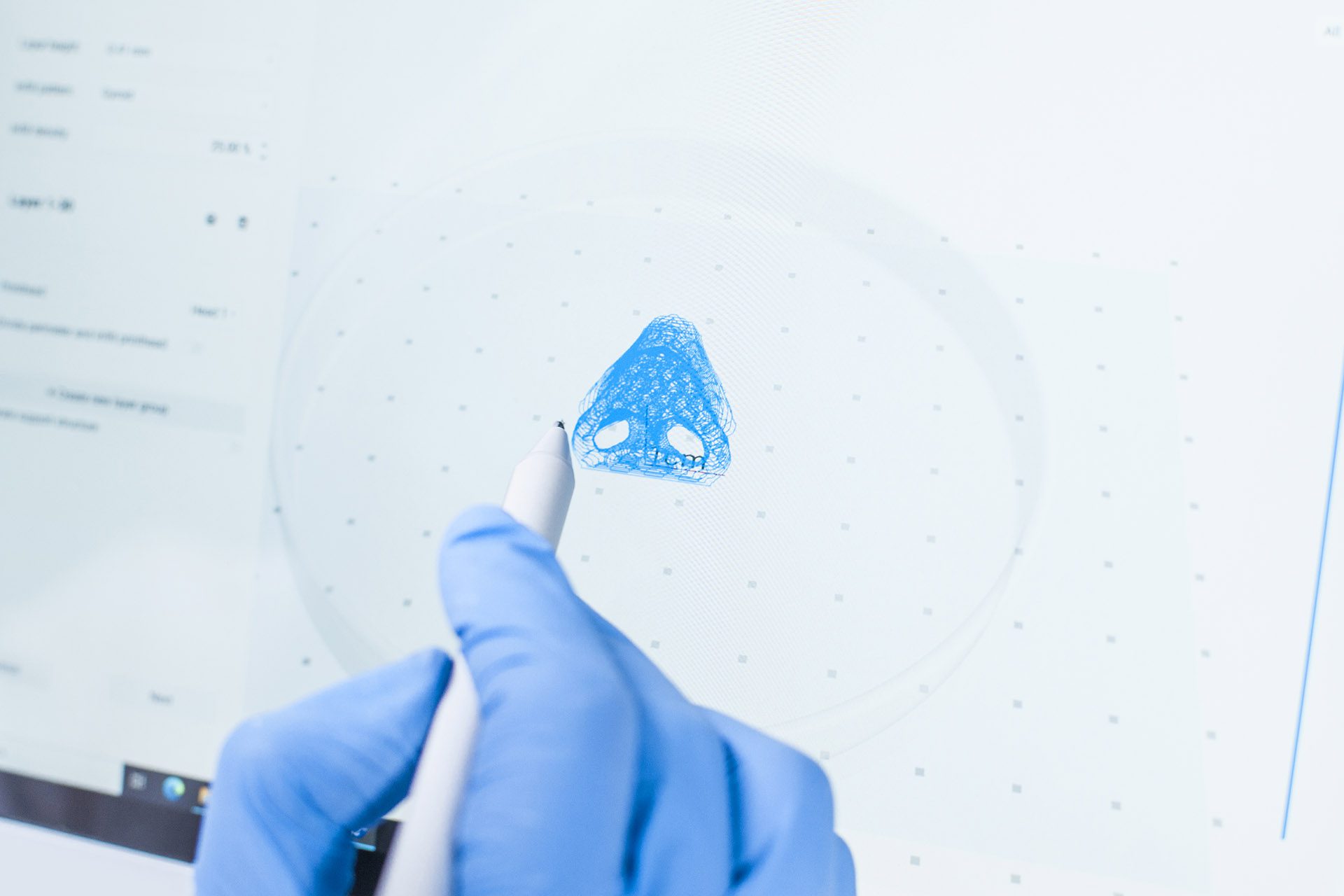

Based on computer numerical control (CNC) machining processes, extrusion-based bioprinting precisely dispenses bio-compatible materials layer by layer, following tool paths generated in slices from 3D models. Our extrusion-based 3D bioprinters are designed with flexibility in mind to give bioengineers the freedom to work with a wider range of biomaterials, opening the door for more relevant tissue engineering.

BIO X™

BIO X6™

Light-based 3D bioprinting

Adapted from stereolithography (SLA) processes, light-based bioprinting produces constructs by initiating chemical reactions that solidify or cure bioinks only where they have been illuminated. With multiple types of light-based technologies, like digital light processing (DLP), they are typically much faster because they cure whole layers simultaneously. Thanks to small points of light in the millions, light-based bioprinters are also able to recreate more intricate details at much higher resolutions.

LUMEN X™ Gen 3

This DLP bioprinter is setting the new standard for light-based 3D bioprinting

Quantum X bio

Biodispensing

The future is created in the present, and bioprinting will change the future of medicine.

Delivering high-quality products and keeping your work cutting edge

CELLINK is a global leader in developing and delivering 3D bioprinting solutions for the life-science industry.

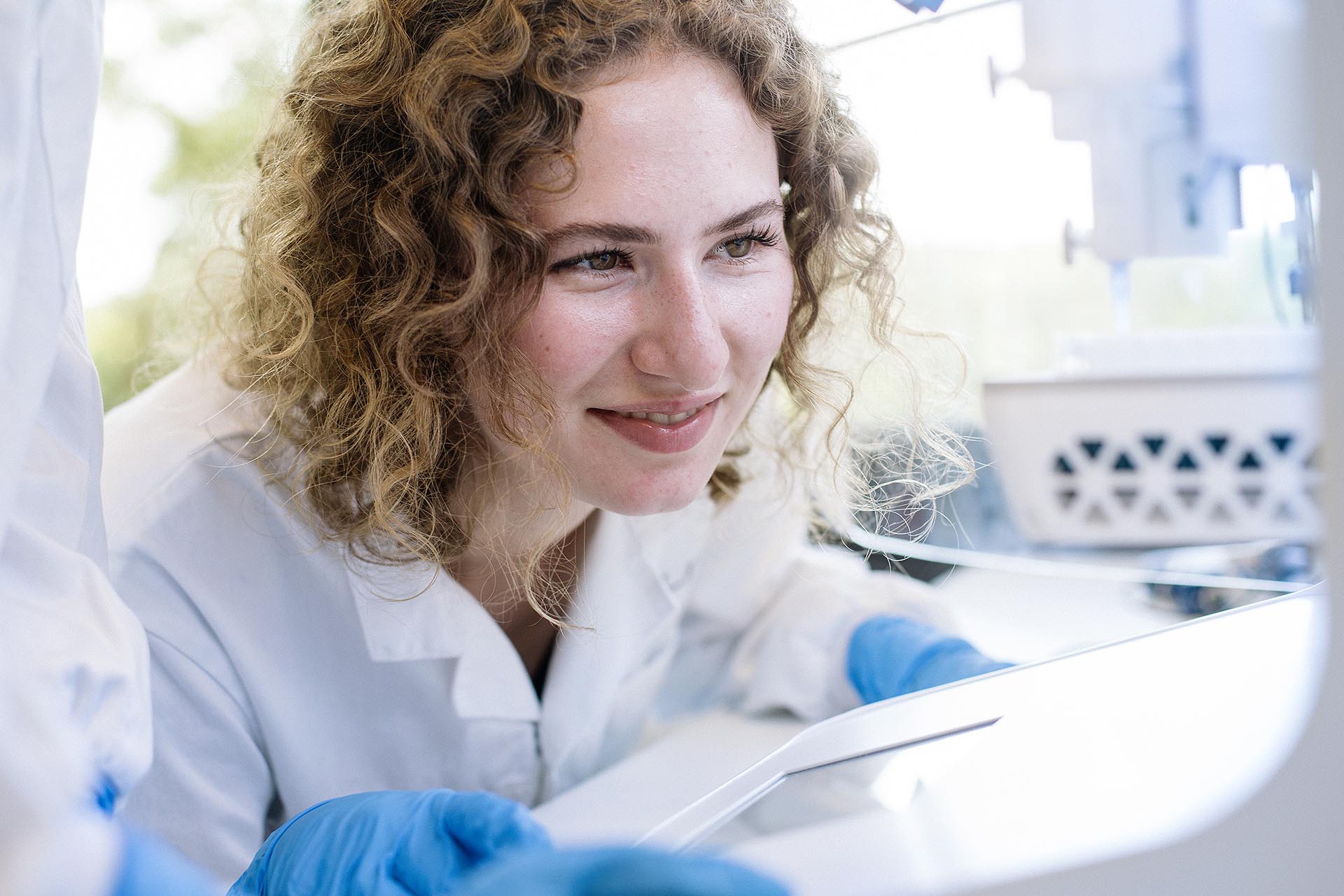

Complete in-house product development and manufacturing

A high-quality team creates high-quality, innovative bioprinters

In order to keep high standards, we do all our production in-house.

Get started now