Ossi Ink

Powered by Ossiform

Bringing new levels of biocompatability to bone bioprinting. Ossi Ink provides researchers with the ideal material for custom in vitro bone constructs.

In vitro bone constructs. On Demand.

Ossi Ink is the first hard tissue in vitro mimetic solution, allowing you to create highly customizable constructs to be printed on demand. It’s composed of β-tricalcium phosphate, a calcium phosphate compound similar to the main mineral found in human bones.

Being able to replicate the physical properties of calcified bone in vitro using Ossi Ink, you are provided with a powerful tool to enhance the reliability and relevance of your experiments, without having to use animal-derived products.

Features designed for you

Endogenous to the human body

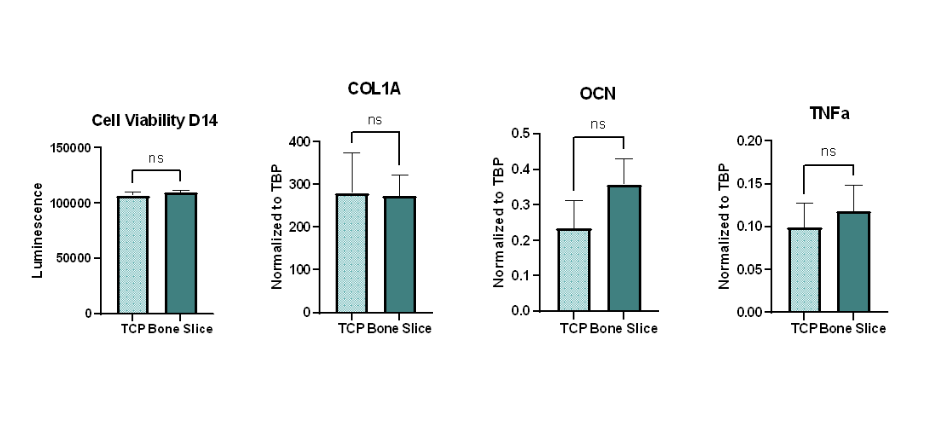

Ossi Ink is comprised of materials endogenous to the human body, thus supporting natural cell adhesion, growth, and behavior. Osteoblasts cultured on Ossi Ink perform to the gold standard of bovine bone slices in terms of cell viability, gene expression (COL1A, OCN, TNFa), biocompatability and microarchitecture.

Tuned mechanical properties

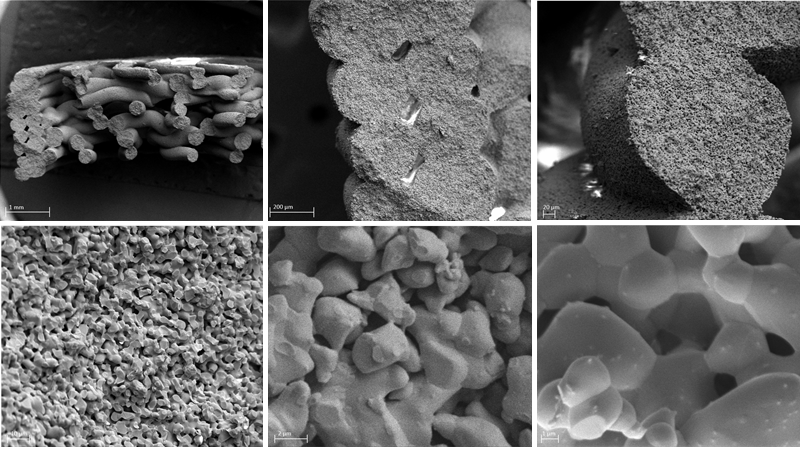

Constructs printed using Ossi Ink mimic the physical and mechanical properties of human calcified bone. Micro-porosities are created within the rigid macro-porous structure, upon sintering the printed constructs.

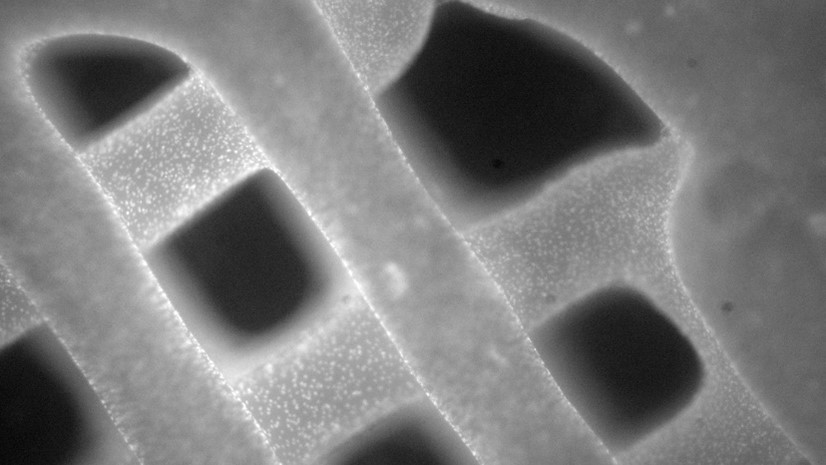

High print fidelity

Take full control of construct scaffolds with high-precision printing with the thermoplastic printhead. Print physiologically relevant constructs with high confidence of cell self-assembly and expansion for long-term cell growth.

Batch-to-batch consistency

Rigorous quality control coupled with the inherent properties of the animal free β-tricalcium phosphate ensures no batch-to-batch variation, ensuring experimental reproducibility.

Application Note

Printing resorbable bone implants suitable for in vitro studies and in vivo bone repair

Read the application note

The bioprinting workflow

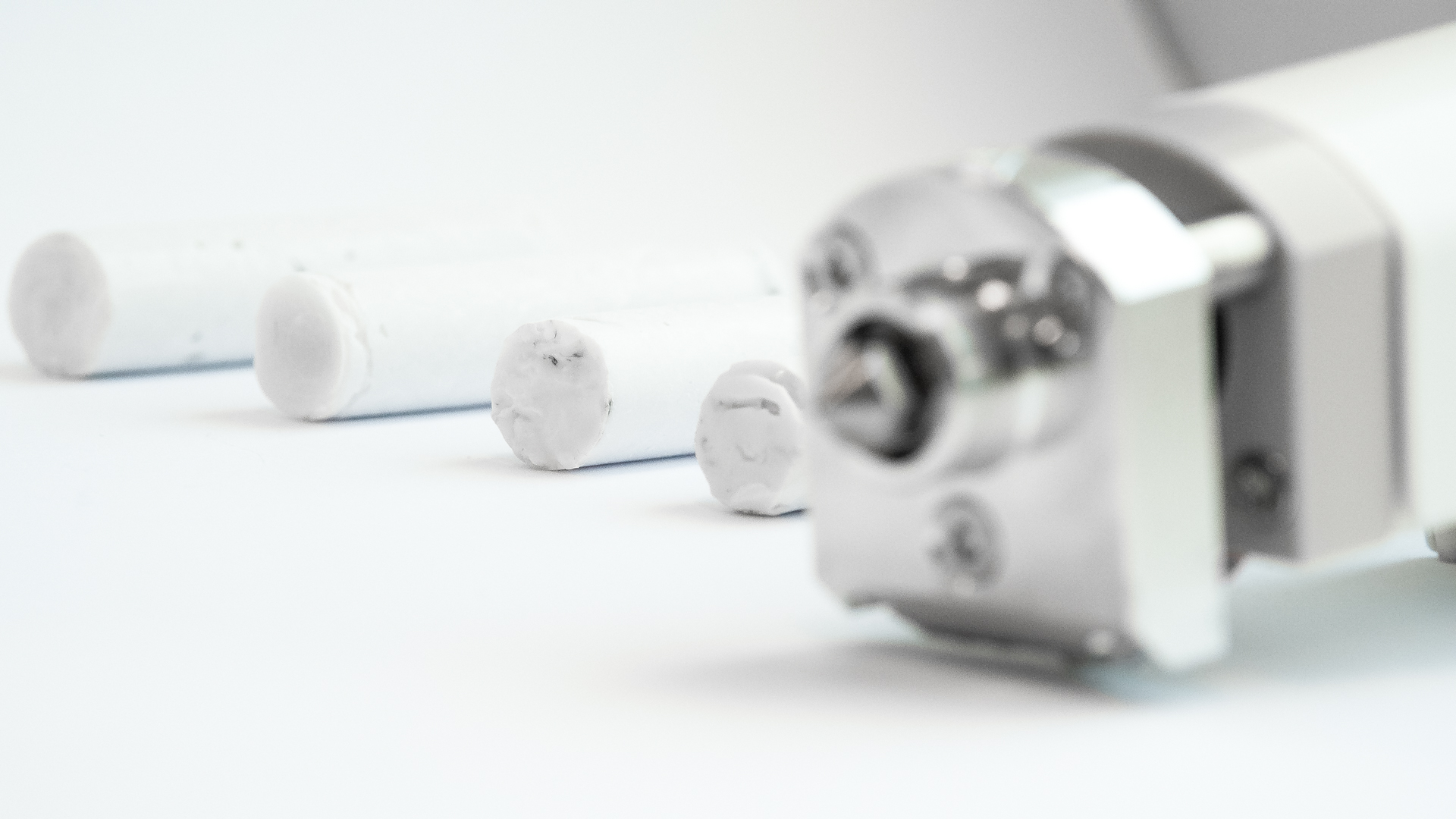

Simply load Ossi Ink into your thermoplastic printhead, heat to 200 °C to fully melt the material. Once melted, set the printhead to 170 °C, and hit go on printing your custom construct.

Sinter

Transform printed constructs into the perfect environment for osteo-cell types with a simple sintering process. Locking in cell and mechanical properties that ensure long-term culture success.

Culture

Seed your cells on to the construct and watch as they relish their environment and begin to exhibit in vivo-like behavior.

Analyze

Extract insights and accelerate discovery with easy-to-follow protocols on typical downstream analysis methods.