Biofabrication of Bioreactors with DLP and Extrusion Bioprinters

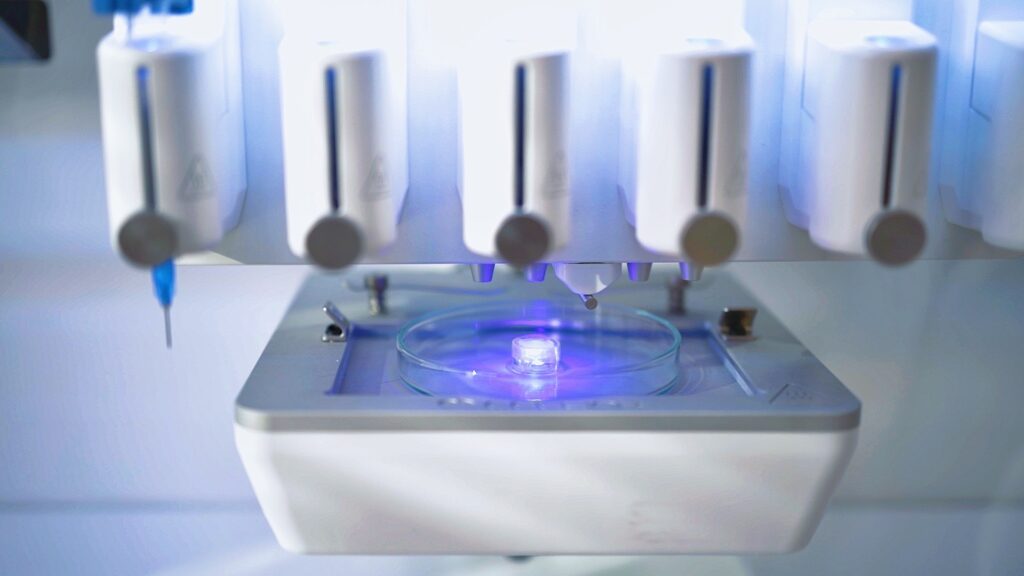

Bioprinting bioreactors can create physiologically relevant environments customizable to specific cell types or bacteria and can help optimize your 3D cell culturing and tissue engineering workflows. This technical note proposes a novel solution for designing and fabricating bioreactors using the LUMEN X DLP-based and the BIO X6 extrusion-based bioprinters. It also discusses additional applications for bioreactors, including suspension cultures, co-cultures, drug-releasing scaffolds, and dynamic flow systems for monitoring cell migration and invasion.

Learn how to:

- Create a living scaffold in a chamber usable as a bioreactor, Transwell system or co-culture chamber.

- Fabricate a closed bioreactor on the high-resolution DLP-based LUMEN X bioprinter.

- Create precise co- and multicell cultures inside a bioreactor with the BIO X6 extrusion-based 3D bioprinter.

- Encapsulate cells in beads and place them in the chamber to perform suspension cultures with systems such as the C.BIRD system (CYTENA).

- Use one medium in the chamber and another in the well to create a bicompartmental configuration.

This technical note is conducted with an old generation of LUMEN X.