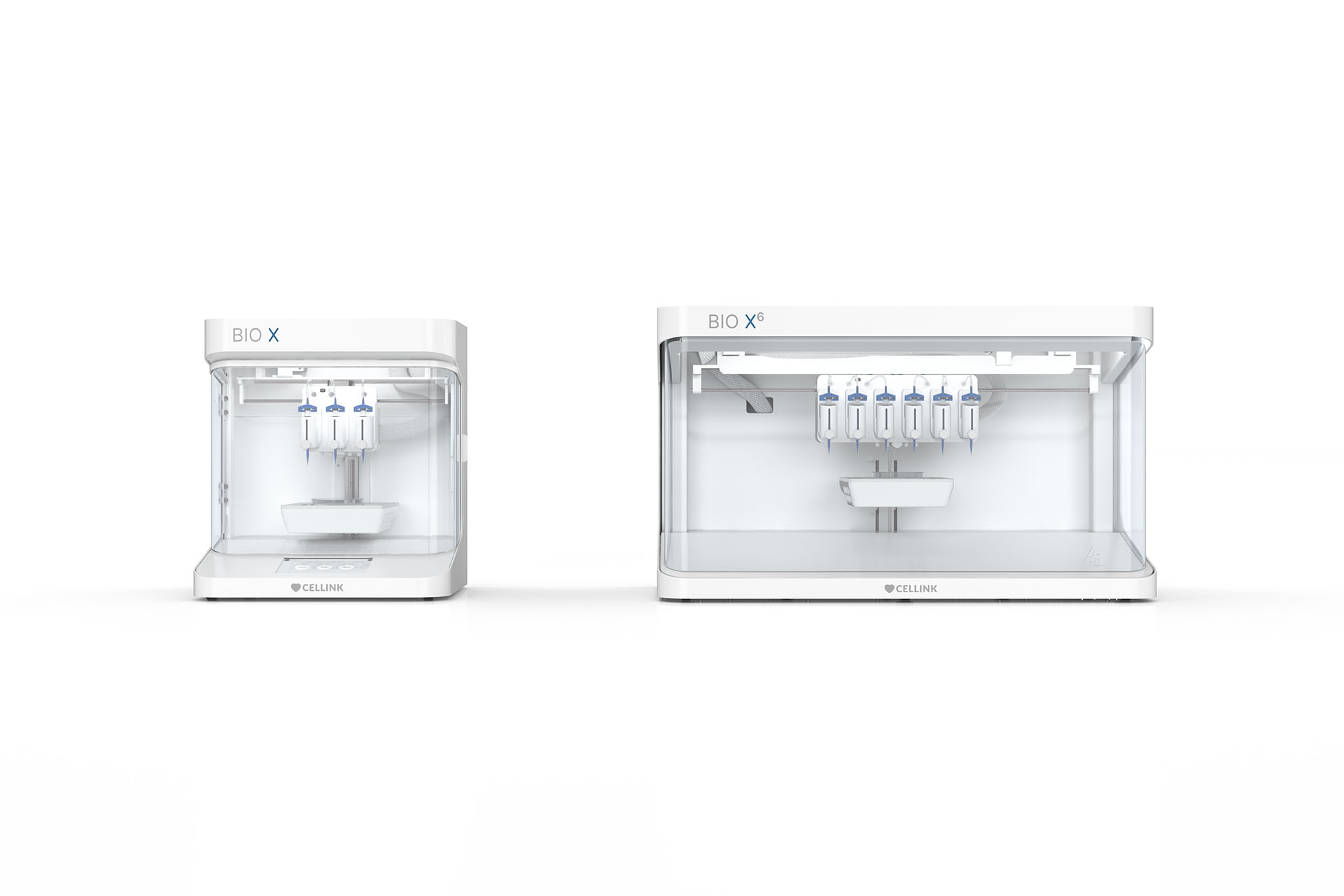

5 reasons to upgrade to the BIO X™ or BIO X6™

1. Our built-in, easy-to-use software

Pushing the limits of science is challenging, but bioprinting needn’t be.

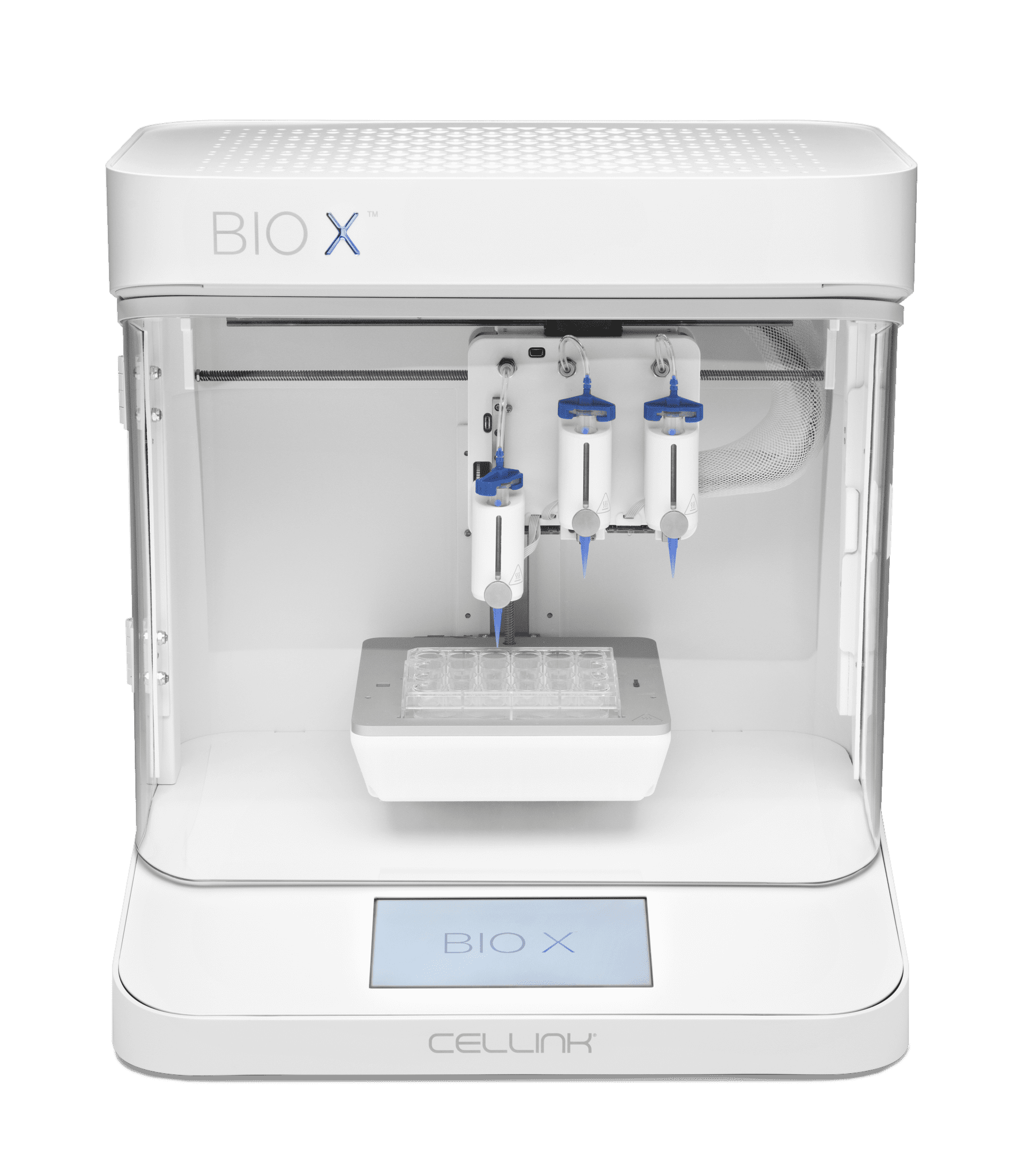

At CELLINK, we work tirelessly to make the wonders of bioprinting accessible to everyone. The BIO X and BIO X6 are ready-to-use, right out of the box. Once they are equipped with a 3D model (.stl file), users can start bioprinting immediately, removing the need for hours of training or tedious g-coding. Through democratizing bioprinting, we hope cell biologists, biomedical engineers and doctors can come together to develop innovative therapies and technologies.

We also offer a range of additional software features, including the assignment of specific layers to different printheads, auto-calibration, and protocol saving. These features improve the complexity and efficiency of your bioprinting workflows.

The BIO X and X6 epitomize user-friendly design, because at CELLINK we believe your focus should be on your research.

2. Our intelligent, future-proof design

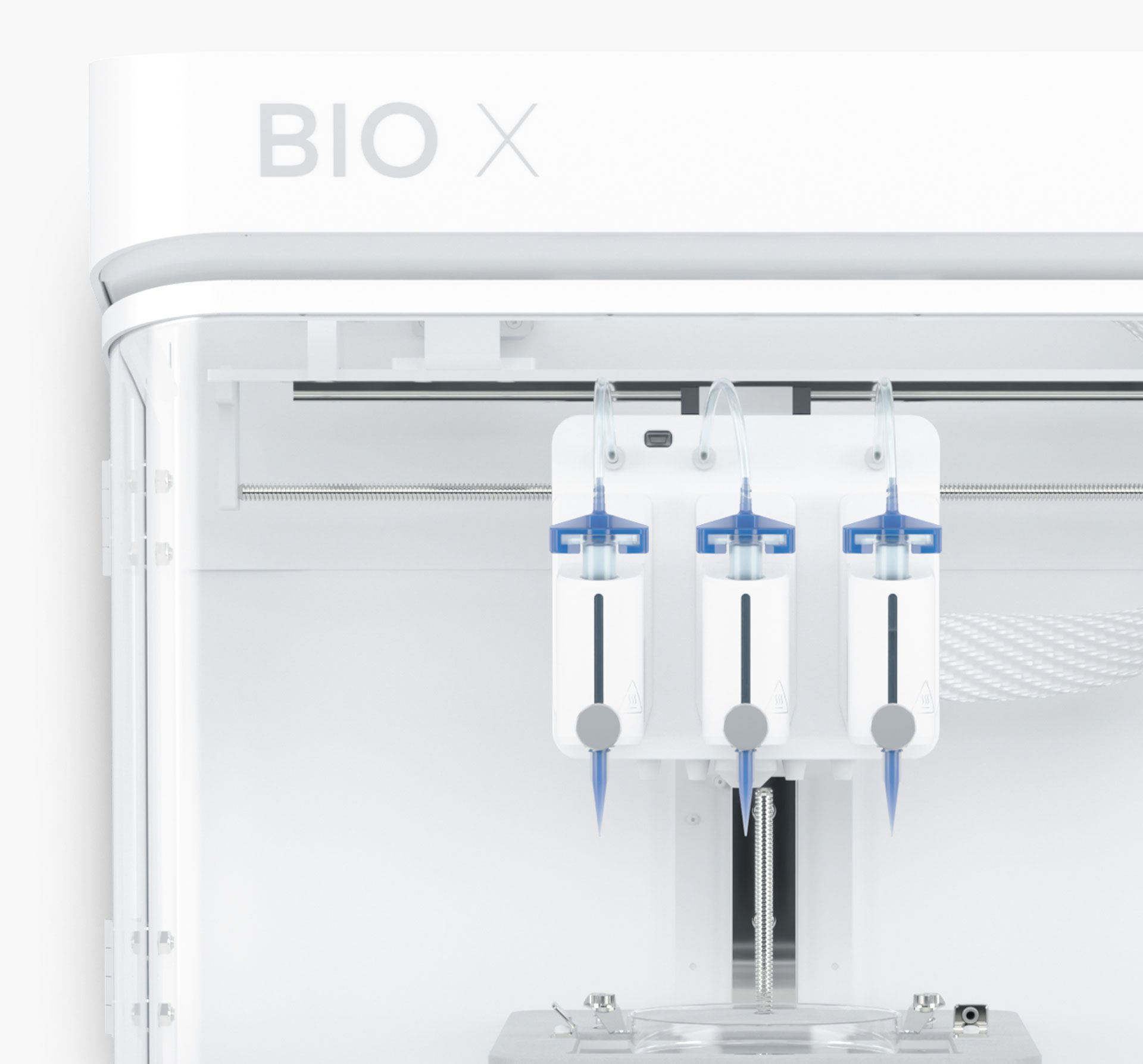

Conventional bioprinters are often limited when it comes to compatible materials or deposition methods. With our intelligent interchangeable printheads, the BIO X and BIO X6 provide bioprinting freedom at every benchtop.

Our modular system allows users to select from 8 printheads and toolheads to develop constructs that best suit their research. The pneumatic printhead leverages air pressure to extrude material out. The thermoplastic printhead can reach 250°C, allowing users to work with synthetic polymers such as PCL, PLA and PLGA.

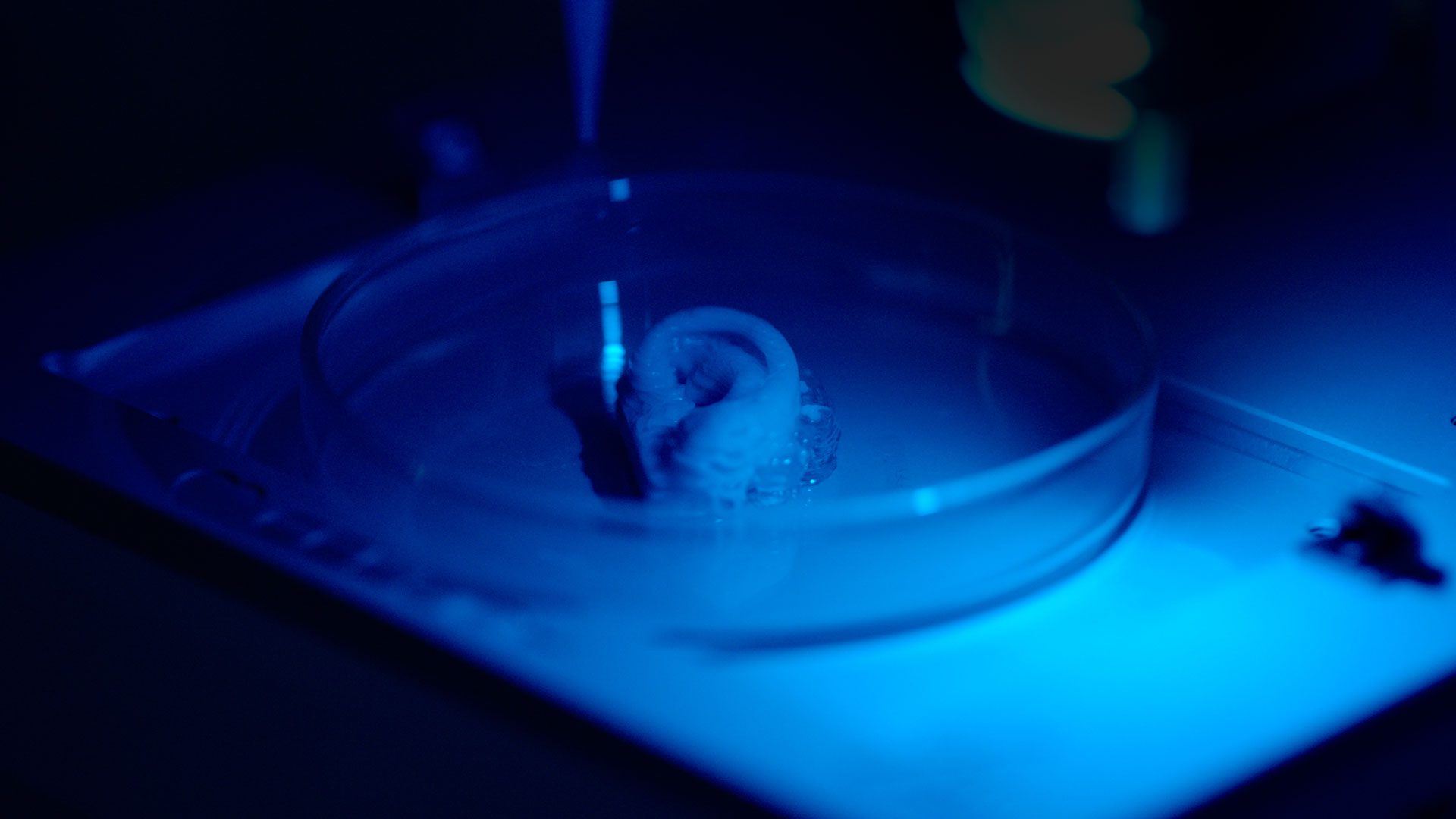

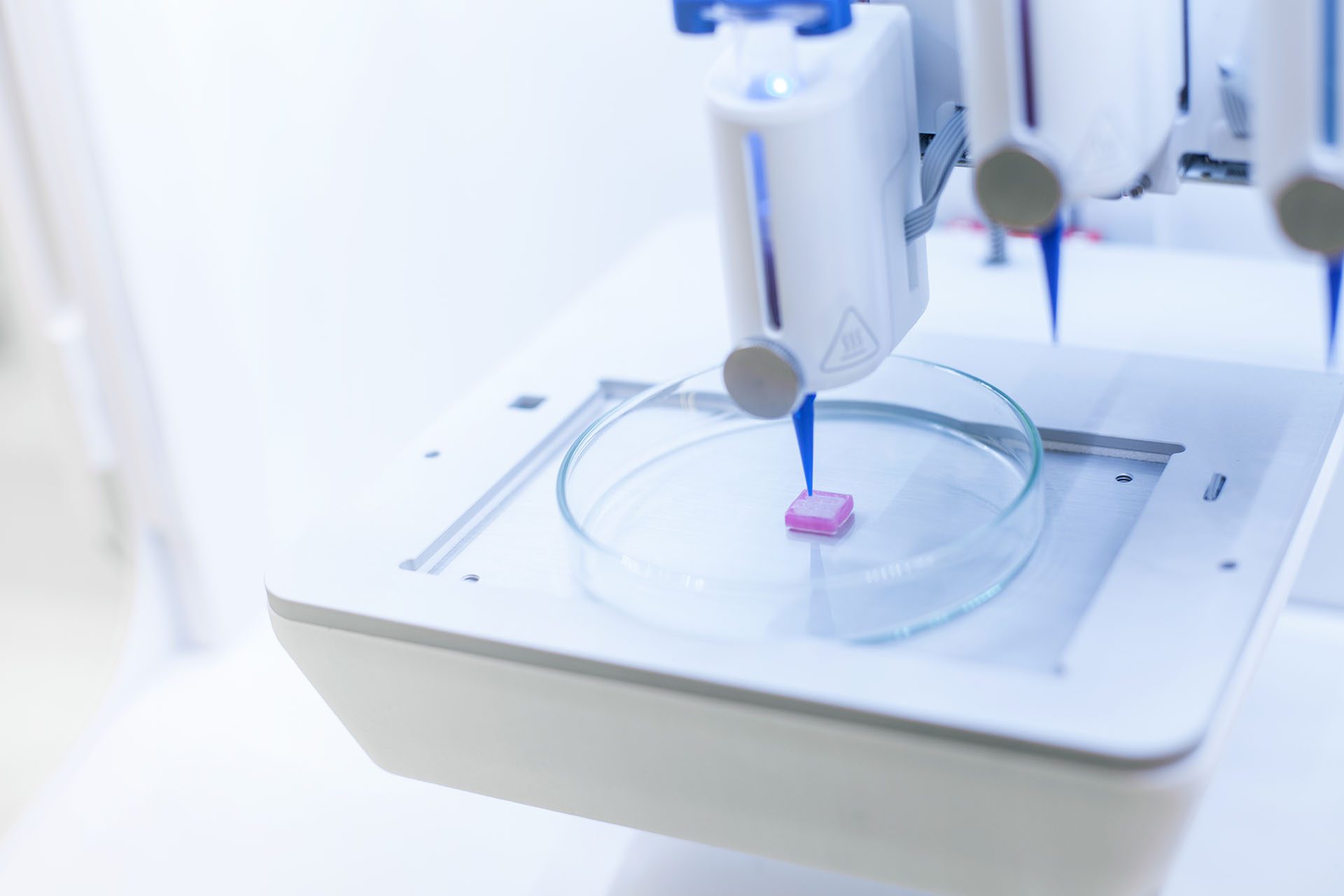

For temperature-sensitive materials like GelMA or Collagen, the BIO X and X6 come with a temperature-controlled printhead as standard. It features a dynamic range of temperature from 4°C—65°C, precisely setting the ideal temperature for each task.

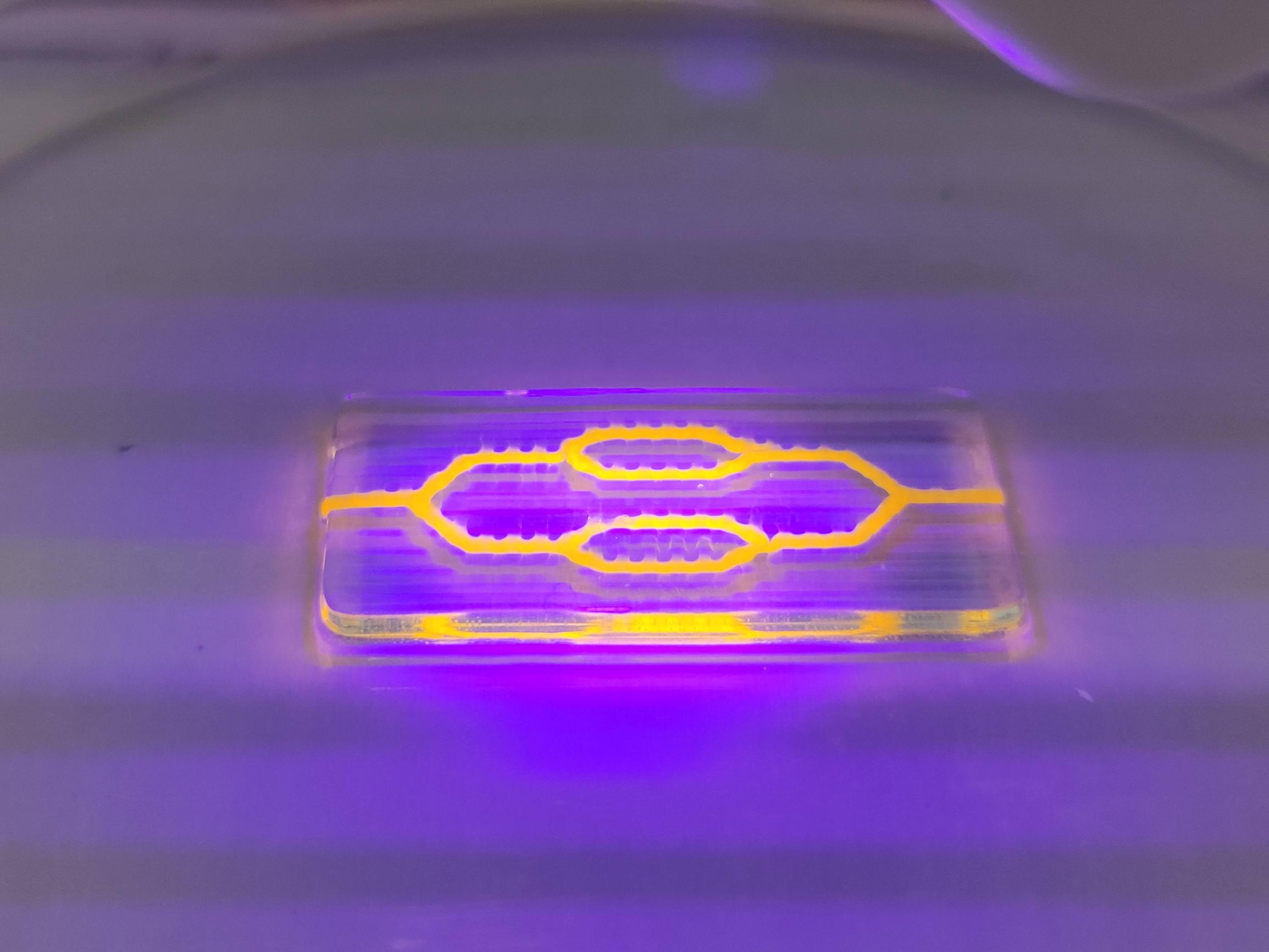

The BIO X and BIO X6 are the only bioprinters that offer multiple modalities of printing in one system. With our syringe pump printhead, users can bring precision associated with mechanical-based extrusion to their research. Our Electromagnetic Droplet printhead can rapidly create spheroids or micro-patterns on constructs. This innovative inkjet-based printhead is a unique offering in the industry.

At CELLINK, we think outside of the box and want to enable our users to do the same.

A customer’s need to develop biomechanical gradients led us to invent our UV curing toolhead. This technology allows the user to deposit light in specific segments of construct, creating effective biomechanical gradients.

With our HD camera toolhead, you can develop robust quality assurance techniques by photographing each print. But most importantly, our interchangeable printhead system guarantees that your bioprinter is future-proofed. As new printheads and toolheads are developed, your bioprinter will continue to grow in functionality.

3. Our innovative clean chamber technology

If your lab was a Monopoly board, then your safety cabinet real estate would be Park Place or Boardwalk. Space is at a premium inside a biosafety cabinet, and rightly so. The BIO X and BIO X6 are designed to be stand-alone systems, without sacrificing stability. As part of our patented Clean Chamber Technology, both the BIO X and BIO X6 utilise HEPA filters and mechanisms to create positive pressure, keeping the printed construct safe from unwanted contaminants. All this, simply from the bench top. The BIO X and X6 are the only commercially available bioprinters offering this versatility.

Continuous cellular work helps us push the boundaries of tissue engineering. With the BIO X and X6, you can be confident that your costly cells are never compromised, while you focus on answering the important questions.

4. The best customer service and technical support in the industry

We don’t expect anyone to take this journey alone.

With a team of more than 400 employees, CELLINK is the premier partner for life science research. We aim to provide end-to-end services to our customers: from on-site installation and training to our premium tier of unlimited application support. At CELLINK, we will work side-by-side with you to drive your work forward.

With 15 international locations, the CELLINK global network ensures we provide timely support to all corners of the world.

Science knows no boundaries, and neither does our commitment to your research.

5. Flexible finance options

With all these benefits, what’s stopping you from upgrading and elevating your research?

The answer may be your budget. We recognize that purchasing capital equipment can be challenging. Navigating tight budgets, government regulations and convoluted purchasing processes is time-consuming. Our finance team has developed a range of plans that offer flexibility when it comes to financing and leasing equipment. Our goal at CELLINK is to make our cutting-edge instruments available to more research scientists around the world.

Find out how your research can be elevated with a BIO X or BIO X6 – get in touch today.